Special Design for Cast Iron Chute Liners - Manganese steel ball mill liner – H&G

Short Description:

Special Design for Cast Iron Chute Liners - Manganese steel ball mill liner – H&G Detail:

Product Description

Manganese Steel Ball Mill Liner in general refers to a kind of casting steel with the Manganese content at 11%~22%, the carbon content at 0.9%~1.5%, mostly higher than 1.0%. Under low impact load, Manganese Steel Ball Mill Liner can achieve HB300~400, Under high impact load, can achieve HB500~800. Different impact load, the Manganese Steel Ball Mill Liner’s surface hardening layer depth can be up to 10~20 mm. High hardness of hardening layer can resist the wear of grinding media. Under the condition of strong impact abrasive wear, Manganese Steel Ball Mill Liner has excellent anti-wear performance, so Manganese Steel Ball Mill Liner widely used in mining, aggregates, coal industries as wear-resistant parts.

Note: Depending upon the various application, we propose suitable profile with appropriate alloy ranging from 12 to 25%.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Ni |

P |

S |

|

|

Manganese Steel Ball Mill Liner |

0.9-1.5 |

0.3-1.0 |

11-22 |

0-2.5 |

0-0.5 |

≤0.05 |

≤0.05 |

≤0.05 |

Physical Property & Microstructure

|

Name |

HB |

Ak(J/cm2) |

Microstructure |

|

Manganese Steel Ball Mill Liner |

≤280 |

≥100 |

A+C |

|

A:Austenite C:Carbide |

|||

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

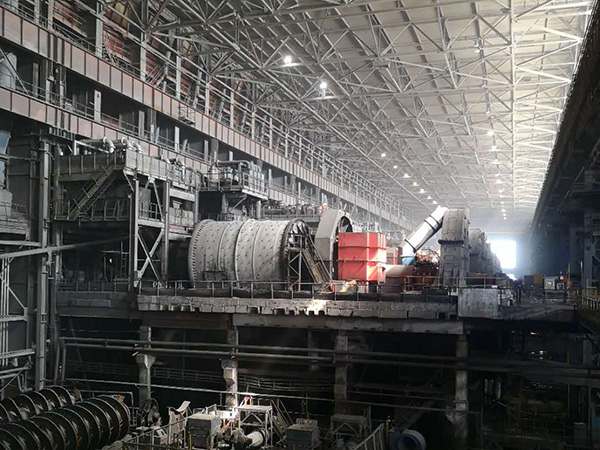

Our Manganese Steel Ball Mill Liner are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

Product detail pictures:

Related Product Guide:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Special Design for Cast Iron Chute Liners - Manganese steel ball mill liner – H&G , The product will supply to all over the world, such as: Thailand, Philippines, Porto, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.