OEM manufacturer Citic Ball Mill - Mn13Cr2 Ball Mill Liner – H&G

Short Description:

OEM manufacturer Citic Ball Mill - Mn13Cr2 Ball Mill Liner – H&G Detail:

Product Description

Manganese Steel Ball Mill Liner in general refers to a kind of casting steel with the Manganese content at 11%~22%, the carbon content at 0.9%~1.5%, mostly higher than 1.0%. Under low impact load, Manganese Steel Ball Mill Liner can achieve HB300~400, Under high impact load, can achieve HB500~800. Different impact load, the Manganese Steel Ball Mill Liner’s surface hardening layer depth can be up to 10~20 mm. High hardness of hardening layer can resist the wear of grinding media. Under the condition of strong impact abrasive wear, Manganese Steel Ball Mill Liner has excellent anti-wear performance, so Manganese Steel Ball Mill Liner widely used in mining, aggregates, coal industries as wear-resistant parts.

Note: Depending upon the various application, we propose suitable profile with appropriate alloy ranging from 12 to 25%.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Ni |

P |

S |

|

|

Manganese Steel Ball Mill Liner |

0.9-1.5 |

0.3-1.0 |

11-22 |

0-2.5 |

0-0.5 |

≤0.05 |

≤0.05 |

≤0.05 |

Physical Property & Microstructure

|

Name |

HB |

Ak(J/cm2) |

Microstructure |

|

Manganese Steel Ball Mill Liner |

≤280 |

≥100 |

A+C |

|

A:Austenite C:Carbide |

|||

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding efficiency, increase production and reduce metal consumption. As the liner in the harsh conditions of long-term conditions, maintenance and replacement of considerable volume, not only requires human, material and financial resources, but also a direct impact on productivity.

Ball Mill Liner plays a major role in protecting the inner wall of the anchor windlass. Different shapes of the ball mill lining plate can improve the grinding effect of the ball mill and improve the working efficiency of the ball mill.

1, flat ball mill liner, the surface smooth, suitable for installation in the fine grinding warehouse.

2, the pressure of the type of ball mill liner, suitable for coarse grinding warehouse, for low speed ball mill.

3, ladder-type ball mill liner, ladder liner is better than the pressure liner, suitable for installation in the coarse grinding warehouse.

4, small corrugated liner crest and pitch are small, suitable for fine grinding and coal mill.

5, end cover liner installed in the grinding head cover or cylinder cover to protect the end cover from wear and tear.

6, ring groove liner in the lining of the T surface for casting a circular groove, after installation to form a circular groove, suitable for multi-warehouse grinding of the first and second positions, dry, wet grinding Machine can be.

7, grading liner, grinding mill for the ideal state should be large particles of material with a large diameter grinding body to impact and crush, that is, in the direction of the mill feed with large diameter grinding body, with the material The direction of the material to the gradual reduction of the grinding body should be sequentially reduced.

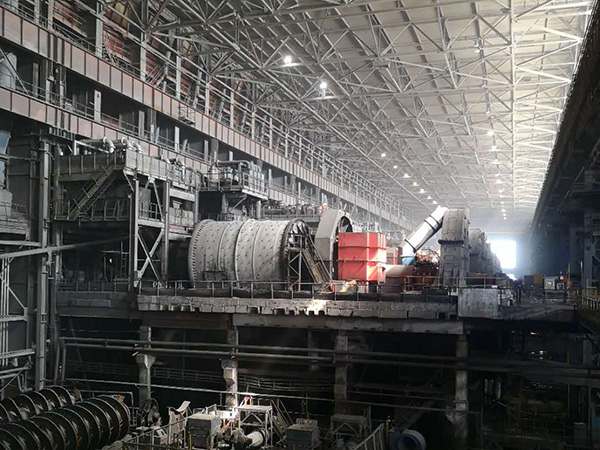

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for OEM manufacturer Citic Ball Mill - Mn13Cr2 Ball Mill Liner – H&G , The product will supply to all over the world, such as: Namibia, Romania, Botswana, With the highest standards of product quality and service, our products have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We are very pleased to serve customers from all over the world!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!