When To Rotate Jaw Crusher Plates?

The perfect circumstance would be when even put on occurs throughout the jaw plate location, making use of all the manganese teeth, eliminating the demand to execute the “turn”, or modification manufacturing.

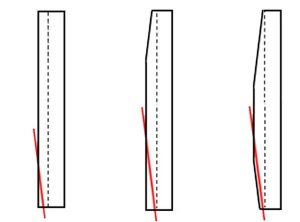

This is difficult, however, due to the fact that there are locations where we can not stay clear of a lot more extreme wear than in others, mainly because of the crushing movement geometry, such as in the fixed jaw plate reduced tip and the central location of the swing jaw plate, so a turn must be carried out to attain much better efficiency and also usage. We suggest a double turn, to put it simply:

Movable Jaw Plate: the same procedure is applied to the swing jaw plate because although the wear occurs in the central area, it rarely occurs in the exact middle of the jaw plate.

Fixed Jaw Plate – use until wear of about 50% occurs in the lower area and make the first turn. Make the second turn when wear from 90% to 100% occurs in this new lower area. Conclude using the remaining 50% of the life cycle of this extremity.

H&G Machinery is the professional crusher jaw plates manufacturer in China. We have the professional engineer wait for your ask!

Mr. Nick Sun NICK@XZHUAGANG.COM

Post time: Oct-30-2020