Western Copper and Gold updates resource for Casino

In its first estimate since 2010, Western Copper and Gold (TSX: WRN; NYSE-AM: WRN) has updated the resource for its 100%-owned Casino project in the Yukonwith more drill results, confirming that it is one of the largest copper-gold deposits in the world.

The new resource includes results from the 2019 drill program and drilling performed from 2010 through 2012 that was unavailable when the company put together its 2010 model; it also incorporates an updated geologic model. The resource remains open at depth.

Casino now has total measured and indicated resources of 2.4 billion tonnes grading 0.14% copper, 0.19 gram gold per tonne, 1.5 grams silver per tonne for 7.6 billion lb. copper, 14.5 million oz. gold and 113.5 million oz. silver. Inferred resources add 1.46 billion tonnes grading 0.10% copper, 0.14 gram gold, 1.2 grams silver for 3.26 billion lb. copper, 6.6 million oz. gold and 55.2 million oz. silver.

In addition, while the heap leach operation won’t recover moly so it isn’t included in the total resource numbers, it will be recovered in the milling operation at a grade of 0.017% moly in the M&I category and 0.010% in the inferred.

CEO Paul West-Sells said the new resource numbers will be incorporated into an updated feasibility study but did not specify a date. He also noted that the company expects that, “in addition to the significantly higher number of tonnes, that the strip ratio should decrease significantly due to the conversion of inferred material to measured and indicated in the pit.”

In a July investor presentation, Western Copper and Gold noted that the estimated C$2.45 billion capex for Casino is “comparable to emerging greenfield and brownfield projects.”

Shareholders in the company include management and the board (12%); private high-net worth individuals (48%); and institutional investors (10%).

Over the last year the company has traded in a range of 44¢ and C$1.90 per share and at presstime in Toronto was trading at C$1.57 per share, up 3.1%. The company has about 115 million common shares outstanding for a C$180 million market cap.

Improvement of fixed jaw plate structure of jaw crusher

One of our China customers who has a PE600*900 jaw crusher to crush Lead-zinc Mine. After a long time running, the fixed jaw plate wear out very quickly. So he asked our engineers to help him to solve this problem.

Reasons for the transformation

According to the operation of pe600 × 900 jaw crusher, through long-term observation, it is found that the main reason for the difficulty in controlling the size of ore discharge opening is the wear of tooth profile of tooth plate. More important is the wear of the fixed plate. However, the main wear parts of the fixed plate are concentrated at 3 / 4 below the centerline of the fixed plate. The wear of the upper part is not large, which is only normal friction wear. Even if there is a certain wear, it will not affect the normal operation of the crusher. That is to say, only 3 / 4 below the centerline of a fixed plate has the maximum force and wear. Only one part of the wear, it is necessary to replace the entire fixed plate, not only time-consuming but also a serious waste of materials. The high cost of crushing directly affects the economic benefits of the concentrator. In view of this situation, under the condition of ensuring the overall structure of the toothed plate, ensuring the crushing cavity shape of the crusher, and keeping the technical parameters unchanged, the fixed toothed plate is divided into fixed plate and working plate. It is an integral tooth plate. In this way, the normal operation of the crusher can be achieved only by changing the working plate. This saves time and material.

Transformation scheme

In the transformation, the working part of the crusher is fixed tooth plate and moving tooth plate. The moving tooth plate is fixed on the moving jaw, and its main wear parts are concentrated in the middle. In the transformation, there is no transformation of the moving tooth plate, but the fixed tooth plate is mainly reformed. After the modification, the overall weight of the fixed toothed plate is increased by 200kg. Since the fixed toothed plate is connected with the frame, the increase of the fixed toothed plate weight has no adverse effect on the whole crusher.

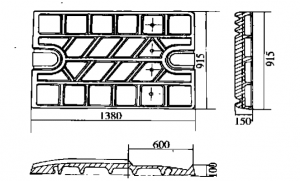

Based on the working characteristics of the crusher, the fixed toothed plate is divided into upper and lower parts about 3 / 4 below the centerline. The working plate and the fixed plate are connected by flat head M30 screw. In order to ensure its strength, the fixed plate is thickened at about 1 / 3 of the centerline. The material is unchanged, and the tooth shape is still zgmn13cr2, as shown in Fig:

@Nick Sun NICK@XZHUAGANG.COM

Post time: Jul-17-2020