Russia on track to become world’s top gold producer by 2029 – report

Despite some disruptions caused by the covid-19 pandemic, Russia is expected to surpass China as the world’s top gold producer by 2029, achieving average annual growth of 3.7% y-o-y between 2020 and 2029.

This forecast was presented in a report by Fitch Solutions Country Risk & Industry Research, whose experts believe that in the short-to-medium term, strong domestic demand for gold will underpin increasing gold production in Russia.

Despite a 900-case coronavirus outbreak at Polyus Gold’s Olympiada mine in the Krasnoyarsk region of eastern Siberia – which is one of the largest operations on the planet producing 1389.2koz of gold in 2019 – most mines have remained virus-free and operational so far.

Thus, there is some limited downside risk to the current gold production forecast in 2020 but, at the same time, there are other forces playing in favour or Russia’s gold industry.

“Expanding US sanctions and tension between the two countries have incentivized the Russian central bank to increase its gold reserves,” the analysis reads. “Moreover, in early August, the Libya Stabilisation Act is expected to pass through the House of Foreign Affairs Committee, imposing additional sanctions on Russia for its alleged role in escalating the civil war in Libya. The act would allow the Trump administration to freeze funds in American banks, cutting off access to dollar-denominated assets and in turn maintaining elevated domestic demand for Russian gold.”

Palladium

When it comes to palladium, Fitch says that production in Russia is on track to expand in 2020 as the sector has not faced disruptions related to the covid-19 pandemic.

“In fact, Russian palladium producers will benefit from supply disruptions in external markets such as South Africa,” the report states. “Top producer Norilsk Nickel will continue to lead the market for autocatalysts, underpinned by smooth operational capacity and its position as a low-cost producer. On April 30, the company confirmed its production guidance will be maintained for the 2020 fiscal year, expecting to produce 2.65-2.78moz of palladium.”

According to Fitch, given that most palladium mines in South Africa continue to operate below capacity as lockdown restrictions are gradually lifted, production in the country is expected to contract by 8.7% this year, while Russian palladium production is expected to register a 2.5% growth.

How to exchange jaw crusher wear plates? What needs notice when exchanging jaw crusher wear plate?

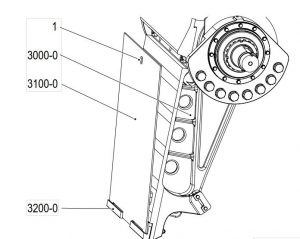

- 3000-0 Jaw (moving)

- 3100-0 Wear plate

- 3200-0 Support bar

- 3200-1 Lifting eye

- Recommended tools: Crow bar, Lifting tackle, and chain Mobile crane

The following wear parts are required:

- New jaw crusher wear plates

- New side wear plates

Some things need notices:

- These instructions are valid for both moving and stationary jaw.

- Remove the jaw plate before removing a wear plate.

- If a jaw shim plate is used, there is no wear plate.

Exchanging jaw crusher wear plates steps:

- Position the hook of a mobile crane vertically above the wear plate (3100-0). Be aware of the weight of the wear plate. Make sure the moving jaw is reclined so that the wear plate will not fall forwards while releasing the upper end. Never stand in the crushing chamber while releasing the upper end with a crow bar.

- Use a crow bar to carefully release the upper end of the wear plate (3100-0) from the jaw (3000-0).

- Attach the lifting hook to the lifting eye (1) on the wear plate (3100-0). Make sure the crane is able to move longitudinally with respect to the jaw crusher.

- Take up the slack in the lifting tackle.

- Carefully lift the wear plate (3100-0) out of the crushing chamber.

- Place the wear plate (3100-0) horizontally on the ground.

- Clean the support bar (3200-0), jaw (3000-0) and corners of the crushing chamber.

- Position the hook of a mobile crane vertically above the new wear plate (3100-0).

- Attach the lifting hook to the lifting eye (1) on the new wear plate (3100-0).

- Take up the slack in the lifting tackle.

- Carefully lift the wear plate (3100-0) into the crushing chamber.

- Place the wear plate (3100-0) on the support bar (3200-0).

- Adjust the wear plate (3100-0) into its correct position.

- Place a crow bar between the wear plate (3100-0) and the deflector plate (moving jaw) or front frame end (stationary jaw).

- Slacken off the lifting tackle.

- Remove the lifting hook from the lifting eye (1).

- Remove the crow bar.

@Nick Sun NICK@XZHUAGANG.COM

Post time: Aug-14-2020