-

Analysis of the Wear Failure of Cone Crusher Liner at Copper Mine

Analysis of the Wear Failure of Cone Crusher Liner at Copper Mine In view of the work conditions of Copper Mine, the analysis of the wear failure of the cone crusher was made. SEM analysis showed that drilling, cutting and squeezing (impacting) of ore which resulted in pits were the domin...Read more -

Application of Insulating and Exothermic Riser In Casting High Manganese Steel Mining Machinery Wear Parts

Application of Insulating and Exothermic Riser In Casting High Manganese Steel Mining Machinery Wear Parts At present, high manganese steel castings are in great demand. Its main products are cone crusher liner, jaw plate, liner plate, blow bars, SAG mill liner, mill liner, etc. With the ...Read more -

High Chromium Blow Bars Production Process

High Chromium Blow Bars Production Process Large impact crusher has the advantages of simple structure, large crushing ratio, and high efficiency. It is widely used in mining, cement, metallurgy, electric power, refractories, glass, and chemical industries. The blow bar is one of the keys...Read more -

Cone Crusher Cavity Types Performance and Improvement

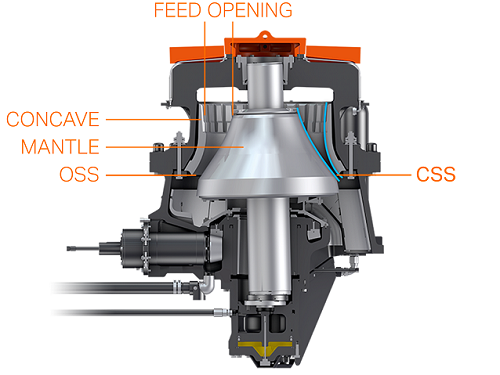

Cone Crusher Cavity Types Performance and Improvement Cone crusher is important equipment for crushing stone. Because of its high production efficiency, fine and uniform discharge, it is widely used in stone processing in mining and construction industries. It can break the stone from the...Read more -

Compare Medium Chromium Steel With ZG40Cr1Mn1MoRe Alloy Steel Mill Liners

Compare Medium Chromium Steel With ZG40Cr1Mn1MoRe Alloy Steel Mill Liners Ball mills are widely used in thermal power plants to crush coal powder. The quality of the ball mill liners, installation, and structure are reasonable, which are related to the safe operation and efficient product...Read more -

High Manganese Cast Steel Metallographic Analysis Standard

High Manganese Cast Steel Metallographic Analysis Standard High manganese steel is widely used to cast crusher wear parts, apron feeder pans, shredder wear parts, and mill liners. It is important to get manganese cast steel metallographic analysis standards. First of all, we need to cut a...Read more -

Effects Of Various Elements In Casting Manganese Steel Parts

Effects Of Various Elements In Casting Manganese Steel Parts Different elements have different functions in manganese steel casting. There are some effects of various elements in casting manganese steel parts. Carbon Element Effection in Manganese Steel Parts Carbon is one of the two most...Read more -

China Austenitic Manganese Steel Castings Standard

China Austenitic Manganese Steel Castings Standard This standard is used for casting kinds of austenitic manganese steel casting parts. 1.Austenitic Manganese Steel Castings Grades And Chemical Composition Grade Chemical Composition % C Si Mn P S Cr Mo Ni W ZG120Mn7Mo1 1.05-1...Read more -

Cone Crusher Maintenance

Maintenance of Cone Crusher Doing frequently set up maintenance on cone crusher is the most critical action in maintaining day-to-day integrity and maximum product outcome. Let it be known that even executing minor cleanup as well as evaluations around and also on cone crushers daily can ...Read more -

Introduction of Famous Cone Crusher Brands

Introduction of Famous Cone Crusher Brands Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Cone crushers are popular rock crushing machines in aggregates production,...Read more -

Cone Crusher Liner Manufacturing Process Introduction

Cone Crusher Liner Manufacturing Process Introduction H&G Machinery has been casted cone crusher wear parts over 30 years. Our cone crusher liner manufacturing process is based on the America standard. Let us check how we cast cone crusher liners. Step 1: Check the drawings with the customer...Read more -

When To Change Cone Crusher Wear Parts?

When To Change Cone Crusher Wear Parts? There are two situations need to change cone crusher wear parts: Situation 1:Normal Abrasion. In order to avoid damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced before they are worn through. In normal c...Read more