Glencore copper production drops 11%, cobalt by third

Glencore Plc (LON: GLEN) said trading profit will be at the top end of its target this year but posted lower production figures for its first half.

The company had nearly $1 billion in earnings before interest and taxes in oil trading in the first six months of 2020, similar to what it made in the full year 2019, Bloomberg reported last week.

In March and April, as oil prices plunged, traders were able to buy and store huge amounts of cheap crude before selling it later at higher prices.

Glencore has set lower full-year guidance for the production of nickel and coal. Guidance for copper, cobalt, zinc and ferrochrome remained unchanged.

“Our marketing business has risen to the challenge, delivering robust counter-cyclical earnings,” Glencore CEO Ivan Glasenberg said in a statement Friday.

“A very strong first-half performance allows us to now raise our full year 2020 EBIT expectations to the top end of our $2.2-$3.2 billion guidance range.”

The company reported copper production of 588,100 tonnes in H1, 74,900 tonnes, 11% lower than H1 2019, mainly reflecting the Mutanda mine in DRC being on care and maintenance, expected lower grades at Antapaccay in Peru and the short-term impact of Antamina’s covid-19 related demobilisation in Peru. The impact was partly offset by stronger milling throughput at Collahuasi mine in Chile.

Glencore narrowed guidance for full year copper production to 1.225m tonnes, plus or minus 35,0000 tonnes.

Glasenberg said the company saw particularly strong operational performance at Katanga, with its ramp-up on track to achieve design capacity by the end of the year.

Cobalt production was down 33% to 14,300 tonnes, but the company retained full year guidance for the metal, at a midrange of 28,000 tonnes.

Glencore’s zinc production was 550,100 tonnes, in line with H1 2019, reflecting stronger grades at the Canadian mines and the various temporary covid-19 related suspensions at Antamina and other South American operations.

Nickel production of 55,200 tonnes was in line with H1 2019, reflecting a strong period of operations at Murrin mine in Western Australia.

Coal production of 58.1 million tonnes was 10.1 million tonnes (15%) lower than H1 2019, mainly reflecting the covid-19 related asset suspensions in Colombia.

Covid-19

While the majority of Glencore’s assets continued to operate through Q2 with minimal disruption, certain operations were temporarily

suspended.

The company said it expects to make up the majority of lost tonnes at its Raglan nickel mine in Quebec over the balance of 2020. At Matagami zinc mine, production restarted in April and it is in line with historical levels, according to the miner.

The Cerrejon open-pit coal mine in Colombia restarted operations in May. Glencore expects FY 2020 attributable production in the 6.5-7.0mt range (2019: 8.6mt).

Operations also restarted in May at Antamina with a reduced workforce and the company expects a phased ramp-up through H2.

Dividend

Glencore warned its net debt, which is already the highest among mining companies, would be higher in the first half of the year.

In March, it deferred a decision to pay a $2.6 billion dividend until interim results next week.

“While we expect our operating cash flow to remain solid, we are ready to adapt to changing market conditions.” said Glasenberg.

“I suspect the company will be under a degree of pressure to pay dividend given the payouts from Rio Tinto and Anglo American,” said BMO Capital Markets analyst Edward Sterck.

Glencore’s stock was down 1.1% on the LSE on Friday (3:13PM BST). The company has a $30.6 billion market capitalization.

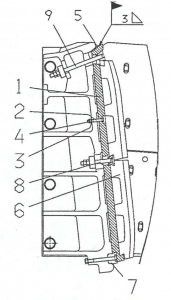

The intermediate plate is an important jaw crusher wear parts. Fitting an intermediate (backing) plate behind the fixed jaw die reduces the nip angle of the crusher. The intermediate plate reduces the feed opening and the setting range by approximately the same amount as its thickness. However, the intermediate plate does not, under normal circumstances, allow the user to use a smaller setting than the minimum recommended setting.

- INTERMEDIATE PLATE

- INTERMEDIATE PLATE BOLT

- INTERMEDIATE PLATE WASHERS

- INTERMEDIATE PLATE NUTS

- FILLING WEDGE

- JAW DIE

- LOWER WEDGE

- CENTER JAW DIE BOLT

- UPPER JAW DIE BOLT

If available with the specific jaw crusher model, an intermediate plate may be used for the following reasons:

1. To improve the nip angle (by decreasing the nip angle) when crushing slippery or round material (material that is difficult to bite).

2. To increase the length of the crushing zone (and thus increase the life of the jaw dies) when the feed material is consistently smaller than the crusher’s input capacity.

The intermediate plate is not available for all models. Moreover, intermediate plates are available in more than one thickness for certain model crushers. Before installing an intermediate plate consult Qiming Machinery if it fits your application.

Before installing the intermediate plate, remove the jaw dies or jaw die from the frame. Clean the contact surfaces of the intermediate plate and the frame and ensure that they are in good condition. Lift the intermediate plate and place on top of the lower wedge (7) or place the guiding surface of the intermediate plate in the groove from where the lower wedge has been removed if the lower wedge has been removed, use its fixing bolts in the intermediate plate. Fasten the plate with bolts (2), washers (3), and nuts (4). Then hammer the wedge (5) between the intermediate plate and frame and weld it to the intermediate plate.

Notice: When welding fastens the ground cable directly to the intermediate plate and as close to the welding point as possible.

After installing the intermediate plate install the fixed jaw dies. Note that the jaw bolts used with the intermediate plate must be longer than standard.

After installing the intermediate plate adjust the crusher setting. If the Crusher is equipped with mechanical setting adjustment, check and adjust the tension spring as well.

@Nick Sun NICK@XZHUAGANG.COM

Post time: Aug-07-2020