Different jaw plates tooth profiles

Different jaw plates tooth profiles suit for different working conditions. If you want to decrease your cost, you must choose the right tooth profiles.

Qiming Machinery’s engineers will show you which tooth profiles suit for which conditions.

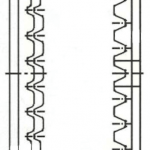

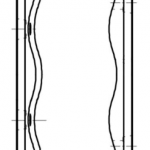

Standard Tooth

- Recommended Usage: Suitable for both rock and gravel crushing.

- Wear life, power requirements and crushing stresses in good balance.

- Typical factory installation.

Quarry Tooth

- Recommended Usage: Suitable for crushing Shot Rock in quarries.

- The flat teeth perform better with abrasive materials; (more wearable tooth material).

- It causes higher stresses and increases power requirements.

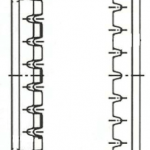

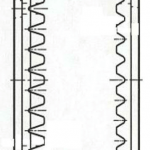

Super Tooth

- Recommended Usage: Suitable for general use and especially a good choice for gravel crushing.

- Large mass and special design of the teeth gives long wear life and allows fine material flow down through the cavity along the grooves without wearing the teeth.

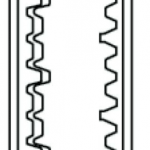

Corrugated Recycling Tooth

- Recommended Usage: Suitable for crushing concrete.

- Fine material flows easily through the cavity along the large grooves.

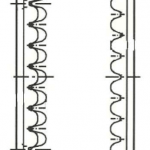

Wavy Recycling Tooth

- Recommended Usage: Suitable for crushing Asphalt Material flows easily down through the cavity along the grooves without packing.

- Normally used in the small setting range with the intermediate plate.

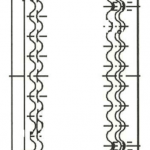

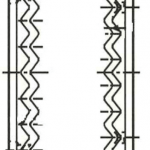

Super Grip Tooth

- Recommended Usage: Suitable for hard and round natural rock crushing.

- It provides a better grip and capacity.

- Fine material flows easily through the cavity along the large grooves.

- Wear life of the fixed and movable jaw dies in good balance.

Wedge and Standard

- Recommended Usage: Suitable for both rock and gravel crushing.

- Thicker lower end of the jaw die and thinner upper end of the jaw die.

- Maximizes size of the maximum feed size of the cavity with the maximum nip angle.

- Wedge jaw die is the fixed one and the Standard jaw die is the movable one.

Anti Slab

- Recommended Usage: Special jaws designed to crush slabby sedimentary rock.

- Can also be used when recycling concrete and asphalt slabs. Available only on special order.

Different Material Different Tooth Types And Application

| Standard | Quarry | Super Tooth | Quarry Thick | Quarry+Super Grip | Anti- Slab |

Recycling | Wavy-Like | ||||||||

| Mn14Cr2 | Mn18Cr2 | Mn18Cr2 | Mn18Cr2 | Mn18Cr2 | Mn18Cr2 | Mn18Cr2 | Mn14Cr2 | Mn18Cr2 | Mn14Cr2 | Mn18Cr2 | |||||

| Blasted Rock | |||||||||||||||

| Difficult & Abrasive | √ | √√√√ | √√√ | √√√√ | √√√√ | ||||||||||

| Difficult & Non Abr. | √√√ | √√√√ | √√√ | √√√ | √√√ | √√√√ | |||||||||

| Medium & Abrasive | √√√ | √√√√ | √√√ | √√√√ | √√√ | ||||||||||

| Medium & Non Abr. | √√√ | √√√√ | √√√√ | √√√ | √√√√ | √√√√ | |||||||||

| Easy & Abrasive | √ | √√√ | √√√√ | √√√ | √√√√ | √√√ | |||||||||

| Easy & Non Abr. | √√√√ | √√√√ | √√√√ | √√√ | √√√√ | √√√ | |||||||||

| Slabby Soft Rock | √√√ | √√√ | √ | √√√ | √√√√ | ||||||||||

| Gravel | |||||||||||||||

| Abrasive | √√√ | √√√√ | |||||||||||||

| Non Abrasive | √√√√ | √√√√ | √√√ | ||||||||||||

| Slippery/Round Rock | |||||||||||||||

| Abrasive | √√√ | √ | √√√ | ||||||||||||

| Non Abrasive | √√√√ | √√√√ | √ | √√√ | |||||||||||

| Asphalt Recycling | √√√√ | √√√√ | |||||||||||||

| Concrete Recycling | √√√ | √√√ | √√√√ | √√√√ | |||||||||||

| Demolition Waste Recycling |

√√√ | √√√ | √√√√ | √√√√ | |||||||||||

| Notice: | √ means can be used; √√√ means good choice; √√√√ means recommended | ||||||||||||||

Mr. Nick Sun NICK@XZHUAGANG.COM

Post time: Oct-30-2020