Coronavirus case emerges at second mine in Papua New Guinea

The novel coronavirus has been detected at a second mine in Papua New Guinea, after an employee at the Lihir Mine owned by Newcrest Mining Ltd tested positive for the disease.

The 30-year-old male, who flew in from Port Moresby at the end of July, is among 26 confirmed cases reported on Sunday by the National Pandemic Control Centre in the capital Port Moresby.

The island nation has now reported a total of 214 coronavirus cases and three deaths.

The Lihir mine case was detected during a routine screening process for all incoming workers who have to observe a mandatory 14-day quarantine period upon arrival on the mine site.

It comes after PNG’s Ok Tedi copper and gold mine suspended operations for at least 14 days from Wednesday, after seven workers tested positive for the novel coronavirus.

While the number of cases in PNG are still low compared with many other countries, they have jumped sharply over the past few weeks.

“This is a critical time for all of us,” National Pandemic Response Deputy Controller Paison Dakulala said in a statement.

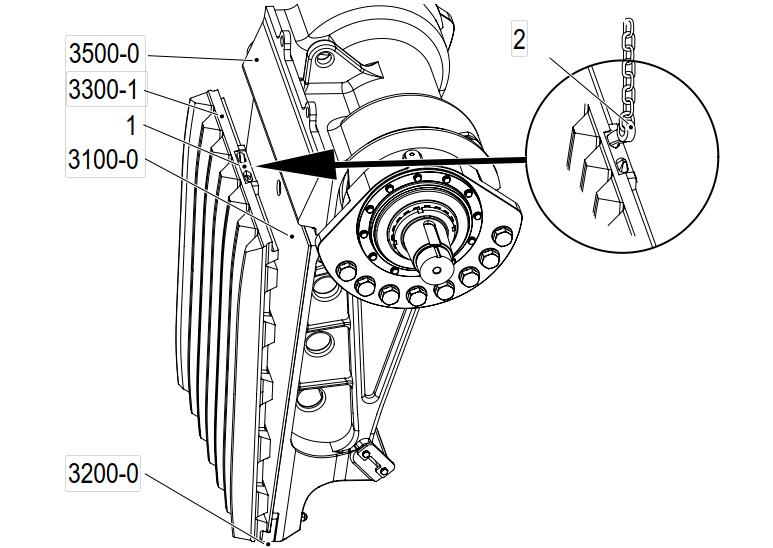

There are some things that need to notice when installing jaw plates.

- 3500-0 Deflector plate (moving jaw)

- 3300-1 Jaw plate

- 3100-0 Wear plate

- 3200-0 Support bar. 1 Lifting cavity,2 Lifting tool.

If planning to exchange wear plates (3100-0), cheek plates, deflector plate (3500-0), and/or support bars (3200-0) at the same time, please proceed to the instructions for those parts before installing the new jaw plate. Replace the support bar screws if they are broken. Remove the support bar and clean it carefully. It’s important that the contact faces of the jaw are clean.

- Clean the wear plate (3100-0), support bar (3200-0), and corners of the crushing chamber.

- Position the hook of a mobile crane vertically above the new jaw plate (3300-1).

- Hang the lifting tool (2) (provided with the crusher) on the hook of the mobile crane and attach the hook of the lifting tool to the lifting cavity (1) on the new jaw plate (3300-1).

- Take up the slack in the lifting tackle. Be aware of the weight of the jaw plate. Handle the jaw plate with care. The tackle should now be tight but not lifting the jaw plate. Keep clear of hanging loads.

- Carefully lift the jaw plate (3300-1) into the crushing chamber.

- Place the jaw plate (3300-1) on the support bar (3200-0).

- Adjust the jaw plate (3300-1) into its correct position.

- Place a crow bar between the jaw plate (3300-1) and the deflector plate (moving jaw) (3500-0) or front frame end (stationary jaw).

- Slacken off the lifting tackle.

- Remove the hook of the lifting tool (2) from the lifting cavity (1).

- Pack a sponge rubber strip or rags into the lifting cavity (1) to keep out dust.

- Remove the crow bar.

- Put two props between the jaws to fix the jaw plates in place until the clamping bars above are installed.

@Nick Sun NICK@XZHUAGANG.COM

Post time: Aug-14-2020