Copper price surges to two-year high

Copper futures prices rallied on Tuesday after the agreement of a massive economic stimulus plan in Europe, optimism about a covid-19 vaccine and ongoing worries about pandemic-hit supply from top producer South America.

Copper for delivery in September trading in New York changed hands for $2.9750 a pound ($6,560 a tonne) in early afternoon trade, up 2% from Monday’s settlement.

Copper futures prices are on track for the highest close in two years and are now up by more than 50% from the covid-19 lows struck in March.

Top-listed copper miner BHP announced on Tuesday that it expects its copper output to fall by between 5% and 14% in its next fiscal year to end-June 2021.

BHP, which part-owns and operates Escondida in Chile, the world’s largest copper mine, said the expected fall in copper production is due to a reduction in its workforce related to covid-19 restrictions.

The Melbourne-based company now expects 2020-2021 copper output of between 1.48m – 1.65m tonnes, down from 1.72m tonnes produced in the year prior.

In a recent note, Capital Economics points out that output rates have fallen sharply in Chile, Peru and Mexico, which together account for 45% of global production.

Output is now at levels last seen in 2017 during a protracted strike at Escondida, which by itself is responsible for nearly 5% of worldwide production.

Surging Chinese imports

Customs data released last week showed China’s unwrought copper imports (anodes and cathodes) in June rose a stunning 50% from the previous month to 656,483 tonnes – a full 15% above the previous monthly record.

June cargoes were double that of the same month last year as the infrastructure and manufacturing sectors in China, responsible for more than half the world’s copper consumption, rapidly recover following the covid-19 slump.

Over the first half of 2020, imports totalled 2.84m tonnes – up 25% year-on-year and on track to easily beat 2018’s annual record of 5.3m tonnes.

June imports of copper concentrate fell unexpectedly, down 6% to 1.69m tonnes from May, but still up 8.4% from June last year, due to disruptions at mines in Peru, China’s top supplier.

Another indication of demand outstripping supply is the decline in treatment and refining charges. TC/RCs paid by miners to smelters have fallen to an eight-year low, a sign of competition between refiners for available concentrate.

For the first six months of 2020 imports total 10.84 million tonnes, on pace to surpass last year’s record-breaking tally of 22 million tonnes.

Hedge fund bulls

Commodity Futures Trading Commission data show hedge fund positioning in the copper market at its most bullish in two years.

Large-scale speculators like hedge funds have built long positions (bets that copper will trade at a higher level in the future) to pre-pandemic levels and at the same time cut shorts (bets that copper can be bought back at a lower price in the future).

As of Tuesday last week, the net balance was a collective long position of 41,309 contracts, up nearly 30% from the week before and the strongest expression of bullish sentiment since June 2018.

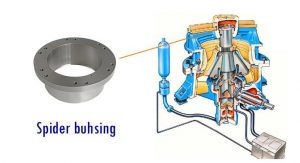

Where is the cone crusher spider bushing location?

The cone crusher spider bushing is located in the top shell and is responsible for supporting the top of the main shaft, and it is one of the most important cone crusher spare parts. Please check in the following pictures:

What is the spider bushing material?

The material for spider bushing is Gray iron: EN-GJL-350.

The raw material is high strength cast iron, with good mechanical property, as well as a good ability to absorb the energy of crusher’s vibration. It’s a great help to make the rotation of the main shaft running steady, which can continuously stable the output of your crusher. The heat treatment of tempering is applied to release the internal stress. It’s a great help to prevent the part’s dimension change in the daily operation of your crusher. It obviously can prolong the life of your crusher. The final machining is carried by the CNC machine to ensure each dimension tolerance, which helps to make your assembly easy and fast, to improve the efficiency of your production and maintenance.

Why the spider bushing is important?

The Spider bushing has an hourglass figure and as such it has a very tight clearance. Once the spider bushing no longer supports the main shaft, the bottom of the main shaft exerts a large amount of force on inner eccentric bushing. If the spider bushing is not maintained, the following problems will happen:

- Burnt inner and outer eccentric bushing;

- Sized main shaft;

- Damaged step bearings;

- Damaged locating bar;

- Damaged main shaft and shaft sleeve.

In one word, not maintaining this item will cause serious damage to the internal mechanical components of your cone crusher.

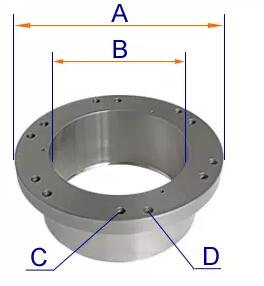

How to measure the spider bushing sizes?

If you want to purchase the spider bushings from us, you can send us your drawings or part number. If you do not have the drawing, let us guide you on how to measure the cone crusher spider bushing drawings.

- Need to measure the external diameter

- Need to measure the inner diameter

- Need to measure the two heights

- Need to measure the install holes

If you have any brands of cone crusher spider bushings inquiries, please send us your drawings or part number to check.

@Nick Sun NICK@XZHUAGANG.COM

Post time: Jul-24-2020