BHP, Curtin University join forces to innovate, produce job-ready graduates

BHP (ASX, LON: BHP), the world’s largest miner, partnered with Curtin University to work on research and innovation projects that will allow the industry to interact with students, researchers and academics to produce job-ready graduates.

In a press release, the resource giant said the alliance is also aimed at achieving sustainable, positive change across industries and sectors.

One of the initial projects involves five research studies that will use environmental DNA or eDNA to help the preservation of species and conservation of important marine features.

Named the eDNA for Global Environment Studies (eDGES), the projects include research to improve monitoring of the endangered/rare Pilbara Olive Python and high-altitude wetlands of international importance in Chile and develop new tests to detect invasive marine species relevant to closure of infrastructure in the marine environment.

“Our researchers are already working to find solutions to our real-world challenges,” Curtin University vice-chancellor, Deborah Terry, said in the brief.

“Our experts in science, engineering and data science are at the forefront of new materials, new manufacturing methods and artificial intelligence. It’s this expertise, innovative thinking and vision for the future Curtin will bring to our alliance with BHP.”

13 Tons of Jaw Plate Production Processing

In the 2008 year, H&G Machinery got an order from a USA customer, who need to produce a big jaw crusher liner. Weight around 13 tons, sizes:4200mm*2300mm*400mm, the tooth face is working face, the back face is installation face, need machining, the material had chosen Mn18 alloy steel.

Material Selection

The basic material composition in the following tab:

| Element | C | Mn | Si | P | S | Mo | Ni |

| Content % | 1.1-1.35 | 17.5-19.0 | ≤0.8 | ≤0.06 | ≤0.01 |

In order to get good Wear resistance, we need to add some “Ni” and “Mo” elements.

Production Processing

- We choose wood to manufacture the big jaw plate pattern.

- The molding sand is sodium silicate chrome ore sand, and the second layer sand is sodium silicate limestone sand, which is conducive to shrinkage after pouring.

- High alumina refractory brick pipe is used in gating system to ensure that molten steel does not contact with molding sand in the runner, so as to reduce sand washing, sand hole, air hole, and other defects; 12 evenly distributed tooth plate sides are used for the inner runner; 4 heating risers are arranged on the side of the toothed plate opposite to the inner runner; sand mold is padded 20cm high on the riser side to facilitate exhaust and improve the feeding effect of fire nozzle; alcohol-based zircon powder is used as coating Paint, brush 2 layers, ignite and burn in time after each painting; check and confirm carefully before closing the box, and fasten evenly with fastening bolts after closing the box.

Melting and pouring

- High-quality cold-rolled sheet metal without oil and rust is selected for scrap. All alloys are tested first. Only high-quality raw materials with definite composition can be put into the furnace.

- The surface of the smelting process is covered with limestone slag to reduce the oxidation and air absorption of molten iron. The molten steel sample before the furnace can be discharged after passing the spectrum analysis and temperature measurement.

- During tapping, the rare earth silicon was modified by the in ladle flushing method to refine the grain size.

- Argon is blown into the ladle to remove impurities and gases. When argon is blown into the ladle, the temperature should be measured to ensure that the pouring temperature meets the process requirements.

- The pouring temperature is controlled at 1410-1425 ℃ and large flow casting is adopted.

- After pouring, cover the riser with an exothermic agent to ensure effective feeding.

Insulation And Cleaning

1. After pouring, the sand at the root of the riser should be shaken off in time to avoid the shrinkage and crack of casting;

2. After unpacking, the riser should be covered with dry sand and cooled slowly;

3. When cutting the riser, cut it off quickly and then cover the cut with dry sand and cool it to room temperature

Heat Treatment

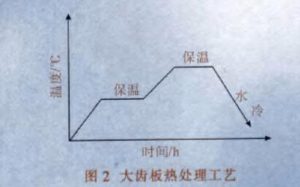

The heat treatment adopts water cooling quenching. The heat treatment process is shown in the figure below:

Results

After 35 days of manufacture time, the customer’s 13 tons jaw plates had finished and sent to USA customer. Around 6 months later, we got this customer feedback that this jaw plate works very well and spans life more than original wear parts.

@Nick Sun NICK@XZHUAGANG.COM

Post time: Jul-17-2020