Manufacturing Companies for Shell Liner - Metso Mining Grinding Mill Liner – H&G

Short Description:

Manufacturing Companies for Shell Liner - Metso Mining Grinding Mill Liner – H&G Detail:

Product Description

White Iron Ball Mill Liner in general refers to the alloy white iron with the chromium content at 12%~26%, the carbon content at 2.0%~3.6%. White Iron Ball Mill Liner distinctive features is that the M7C3 type eutectic carbide micro hardness is HV1300~1800. White Iron Ball Mill Liner’s eutectic carbide is distributed on the base, martensite(the most hard metal matrix organization), in discontinuous network and isolation, which reduces the fragmentation of the matrix effect. As a result, the high chromium Ball Mill Liner has high strength, strong toughness and good wear resistance features , which is widely used at Mining ,Cement and power industry.

White Iron Ball Mill Liner is recommended to be using at low impact working condition such as:

1. Belt conveyor liner for Mining industry.

2. Cement plant Ball Mill.

3. Chemical industry Ball Mill.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High Cr Ball Mill Liner Cr26 |

2.5-3.3 |

0-0.8 |

≤2.0 |

23–28 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

|

High Cr Ball Mill Liner Cr15 |

2.3-3.3 |

0-0.8 |

≤2.0 |

14–18 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

|

Name |

HRC |

Ak(J/cm2) |

Microstructure |

|

High Cr Ball Mill Liner Cr26 |

≥58 |

≥3.5 |

M+C+A |

|

High Ball Mill Liner Cr15 |

≥52 |

≥4.5 |

M+C+A |

|

M-Martensite C- Carbide A-Austenite |

|||

Note: Adjust the chemical content or add other alloying elements of Ball Mill Liner according to customer needs is available.

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

Our White Iron Ball Mill Liner are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

When it comes to chrome moly white iron mill liners, H&G Mill Liners had focused this material for long time. Our chrome moly white iron mill liners span life more than other foundries mill liners.

This cast material is considered to be the ultimate developed and used to date for abrasion resistance in Milling. It is commonly used in cement mills and some of the largest Ball Mills in the world and where performance has not been bettered to date.

The Features

- 600 to 700 BHN white iron

- Large ball mills

- Malleable Iron: cast as white iron,then malleabilised, or heat treated, to impart ductility. Consists of tempered graphite in an a-ferrite or pearlite

matrix - Common in cement mills

- Used for abrasion resistance

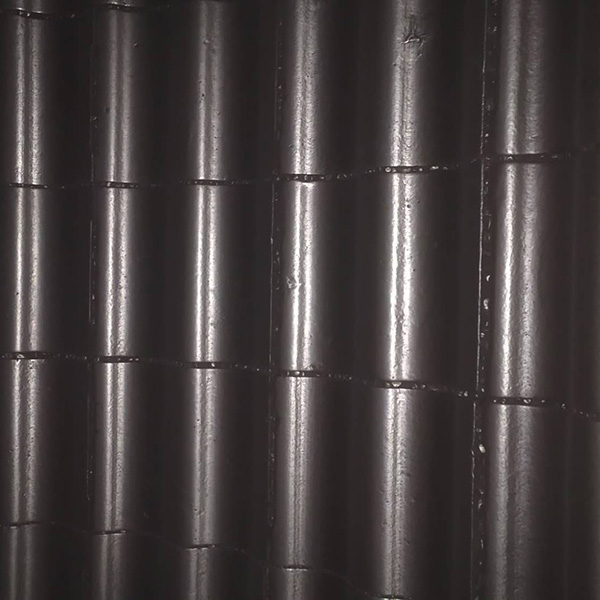

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Manufacturing Companies for Shell Liner - Metso Mining Grinding Mill Liner – H&G , The product will supply to all over the world, such as: luzern, Los Angeles, Nepal, Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!