Low price for Wearing Parts - Grinding Ball Mill SAG Mill AG Mill and Rod Mill Use High Manganese Ball Mill Liner – H&G

Short Description:

Low price for Wearing Parts - Grinding Ball Mill SAG Mill AG Mill and Rod Mill Use High Manganese Ball Mill Liner – H&G Detail:

Product Description

Manganese Steel Ball Mill Liner in general refers to a kind of casting steel with the Manganese content at 11%~22%, the carbon content at 0.9%~1.5%, mostly higher than 1.0%. Under low impact load, Manganese Steel Ball Mill Liner can achieve HB300~400, Under high impact load, can achieve HB500~800. Different impact load, the Manganese Steel Ball Mill Liner’s surface hardening layer depth can be up to 10~20 mm. High hardness of hardening layer can resist the wear of grinding media. Under the condition of strong impact abrasive wear, Manganese Steel Ball Mill Liner has excellent anti-wear performance, so Manganese Steel Ball Mill Liner widely used in mining, aggregates, coal industries as wear-resistant parts.

Note: Depending upon the various application, we propose suitable profile with appropriate alloy ranging from 12 to 25%.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Ni |

P |

S |

|

|

Manganese Steel Ball Mill Liner |

0.9-1.5 |

0.3-1.0 |

11-22 |

0-2.5 |

0-0.5 |

≤0.05 |

≤0.05 |

≤0.05 |

Physical Property & Microstructure

|

Name |

HB |

Ak(J/cm2) |

Microstructure |

|

Manganese Steel Ball Mill Liner |

≤280 |

≥100 |

A+C |

|

A:Austenite C:Carbide |

|||

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

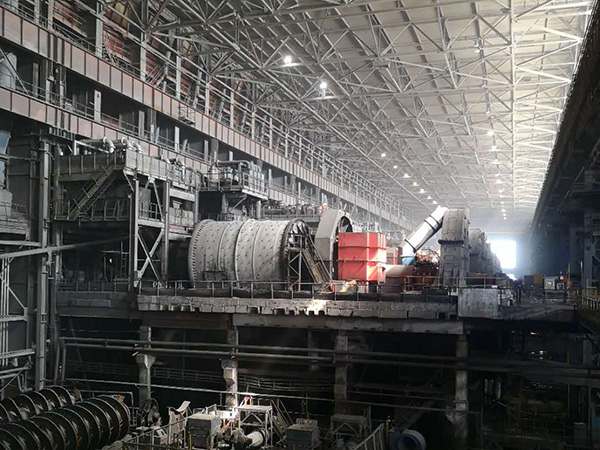

High manganese steel ball mill liner is used to protect the direct impact and wear of grinding ball and materials. At the same time, the different shapes of high manganese steel ball mill liners are used to adjust the movement state of the mineral, thereby enhancing the efficiency of grinding and crushing, which is helpful to improve the grinding efficiency, increase the output and reduce the mental consumption.

Main applications:

● High manganese steel ball mill liner can be used for ball mill, crushers, loaders, excavators, Cutting tools, bulldozers, digging bucket and knife plate, screw conveyor and other wear-resistant structural parts production equipment, by gas cutting processing and various welding, despite the steel sheet with high strength , but cold bending performance well, it can be cold forming.

● Metallurgical industry: mainly used in sintering and ironmaking etc., bin liner, skip, pipes, cloth feeder and base, hopper, pipes, pump case, crusher parts, slag troughs, fans, vibrating screen;

● Cement industry: the impact plate, pipe, pump case, mill liners, crusher parts, slag troughs, a variety of chassis, vibrating screen and so on.

● Power industry: the ash pipe, hopper, fan blades, combustion pipelines, tanks and transport material bucket liners, crusher parts, mill parts, air handling systems and transport aircraft.

● Coal industry: mainly used for coal washing and mining and mineral transport, truck cargo tank liner, bin liners, transporting tank lining, crusher unit, cover plate, wear bars and wear plates.

Three characteristics:

1.High wear and impact resistance

With scientific and reasonable formulation of alloy elements, the high manganese steel liner is multivariate micro-alloying on the basis of the original high-manganese steel, then it has good physical and chemical properties, such as the hardness HRC52-56, the impact toughness value larger than 150J, using life is more than twice as high manganese steel. So it can tolerate a huge impact strength. In a long-term work it can keep lining surface state so ensure a stable increase of more than 5% of production.

2. High strength, high toughness

By using the special quenching medium agent with thermal stability in the quenching process, high manganese steel liners combine high strength, high hardness and high toughness perfectly, which can satisfy high wear resistance and high impact loads process requirements.

3.High cost-effective, strong adaptability

Through the reasonable alloying elements and advanced process of our company, high manganese steel liner has a high quenching hardness, high toughness characteristics. So that it not only has good wear resistance, but also shows excellent price compared with the ordinary liner. It can adapt to mine wet grinding, dry grinding, mixing mill and etc. High manganese steel liners use advanced heat treatment process and change the height of ball mill’s peak, trough. These all help improve grinding rate of ball mill and increase the 20% of machine-hour capacity.

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Low price for Wearing Parts - Grinding Ball Mill SAG Mill AG Mill and Rod Mill Use High Manganese Ball Mill Liner – H&G , The product will supply to all over the world, such as: Belgium, Mexico, Palestine, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.