Low MOQ for White Iron Hopper Liner - White iron ball mill liner – H&G

Short Description:

Low MOQ for White Iron Hopper Liner - White iron ball mill liner – H&G Detail:

Product Description

White Iron Ball Mill Liner in general refers to the alloy white iron with the chromium content at 12%~26%, the carbon content at 2.0%~3.6%. White Iron Ball Mill Liner distinctive features is that the M7C3 type eutectic carbide micro hardness is HV1300~1800. White Iron Ball Mill Liner’s eutectic carbide is distributed on the base, martensite(the most hard metal matrix organization), in discontinuous network and isolation, which reduces the fragmentation of the matrix effect. As a result, the high chromium Ball Mill Liner has high strength, strong toughness and good wear resistance features , which is widely used at Mining ,Cement and power industry.

White Iron Ball Mill Liner is recommended to be using at low impact working condition such as:

1. Belt conveyor liner for Mining industry.

2. Cement plant Ball Mill.

3. Chemical industry Ball Mill.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High Cr Ball Mill Liner Cr26 |

2.5-3.3 |

0-0.8 |

≤2.0 |

23–28 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

|

High Cr Ball Mill Liner Cr15 |

2.3-3.3 |

0-0.8 |

≤2.0 |

14–18 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

|

Name |

HRC |

Ak(J/cm2) |

Microstructure |

|

High Cr Ball Mill Liner Cr26 |

≥58 |

≥3.5 |

M+C+A |

|

High Ball Mill Liner Cr15 |

≥52 |

≥4.5 |

M+C+A |

|

M-Martensite C- Carbide A-Austenite |

|||

Note: Adjust the chemical content or add other alloying elements of Ball Mill Liner according to customer needs is available.

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

Our White Iron Ball Mill Liner are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

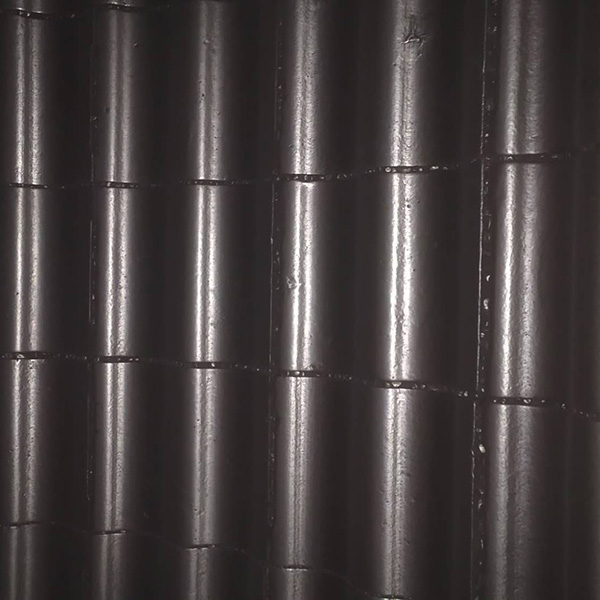

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and exceptional good quality manage throughout all stages of production enables us to guarantee total shopper satisfaction for Low MOQ for White Iron Hopper Liner - White iron ball mill liner – H&G , The product will supply to all over the world, such as: Angola, UAE, Iran, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.