Hot-selling High Chrome White Iron Blow Bar - Hammer crusher spare parts – H&G

Short Description:

Hot-selling High Chrome White Iron Blow Bar - Hammer crusher spare parts – H&G Detail:

Product Description

HAMMER CRUSHER SPARE PARTS is manufactured with high chrome white iron steel Cr20, Cr26, Cr28, Cr30; high chrome with special alloy or High Manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2, high manganese with special alloy. which employ the external refining technology effectively reduced the harmful elements, impurity, oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel. Using proprietary metamorphic agent for modification treatment, fine grains, improve carbide configuration and distribution, and to improves the abrasion resistance and tenacity. After heat treatment

process, the hardness of HAMMER CRUSHER SPARE PARTS can reach to HRC25-65.

MAIN BRANDS SUPPORT:

Metso, Sandvik, Barmac, SVEDALA, Omnicone, EXTEC, Maxtrak, Keestrack, Symons, Hazemag, Cedarapids, Telsmith, McCloskey, Trio, Powerscreen, Kleemann, Terex, Pegson, Kue Ken, Parker, Shanbao, SBM, Zenith, LIMING, MINYU and other famous brands.

AS PER CUSTOMERS’ DRAWINGS AND TECHNOLOGY REQUIREMENT.

Product Package

Steel Pallet. and Customized according to special packing requirement

Application

Metal crusher is an important equipment in metal recycle metal material and recycle concrete production, road-building and construction waste recycle etc. Our HAMMER CRUSHER SPARE PARTS are widely used in the mining industry, stone crushing plant, aggregate / quarry plant, construction /metal industry and others.

Hammer head is the main working parts of the hammer crusher. Hammer weight, shape and material have a significant impact on the production capacity of the crusher. Proportional to the size and weight of the hammer hammer kinetic energy, namely the heavier hammer, hammer kinetic energy, the greater the higher crushing efficiency. However, the greater the weight of the hammer, spin up the greater the centrifugal force generated on other parts of hammer crusher rotor should have an impact and damage, therefore, the weight of the hammer to moderate. There are dozens of big hammer weight kg small, only a few kilograms, usually not more than 80 kg. Hammerhead reasonable choice material is very important, ordinary carbon steel hammer heads for crushing limestone, will wear off within a few days, but with the hammer high manganese steel casting, heat treatment, surface hardening it, you can use a long time. The hammerhead materials and design used was ZGMn13 high manganese steel, a material with high wear resistance, and can withstand shock loads.

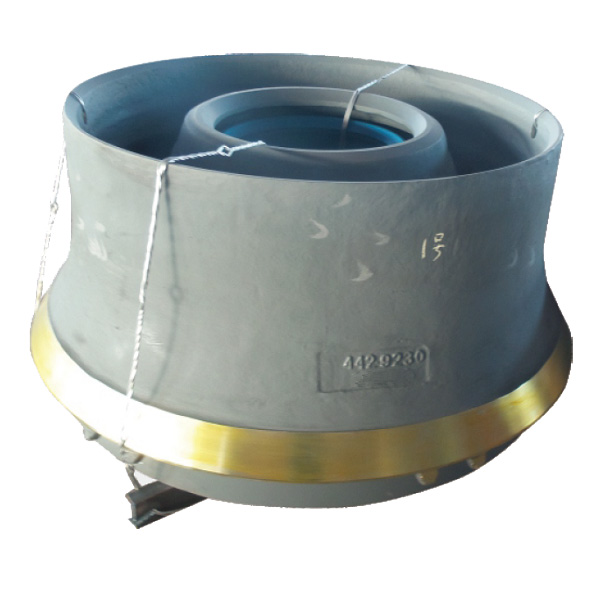

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Hot-selling High Chrome White Iron Blow Bar - Hammer crusher spare parts – H&G , The product will supply to all over the world, such as: Switzerland, Buenos Aires, US, Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.