High Quality Sag Mill Bolts - Support Roller – H&G

Short Description:

High Quality Sag Mill Bolts - Support Roller – H&G Detail:

H&G supplying all the accessories for grinding mills, such as mill end cover, mill hollow shaft, girth gear, mill discharge screen, roller shaft, rollers etc.

Ball mill end cover is one of the key part of ball mill, its structure is relatively complex, long production cycle, high precision of processing and assembling, so when compiling process routes, should fully consider its manufacturability.

Ball mill end cover is slightly conical in general, which is considering the configuration of main bearing. Large and medium-sized ball mill end cover are mostly manufacturing by cast steel, the ductile cast iron is used for the small type ball mill. In order to ensure concentricity of the end cover axis and the cylinder axis, usually the end cover and shaft neck will casting together. But in the case of equipment ability is not enough, also can casting respectively, after processing fastening them together, and then to do mechanical processing.

Girth gear is a main part of dryer and ball mill machining. It needs to work for very long time to have the whole barrel to rotate. So customer requirements for large ring gear is very high and strict.

Girth gear is a rotary kiln, mill main transmission parts and other equipment, mainly driven by the motor pinion drive, pinion drive mounted on the barrel of a large gear, so that the mill drive, large gear and the barrel cooperation.

Due to the girth gear modulus big, big diameter, the ring gear of our company processed using radiation plate structure, a combination of two half-ring together.

| Product Name |

Ball Mill End Cover/ Hollow Shaft |

|

Material Standard |

ASTM/GOST/JIS/DIN/EN/GB |

|

Structure |

Casting |

|

Process |

Lathing, Milling, Drilling |

|

Heat treatment |

Surface Quenching |

|

Certificate |

ISO |

|

Type |

According to Drawing |

|

Package |

Standard Export Packing |

|

Delivery time |

30-90 days |

|

Certification |

ISO9001-2008 |

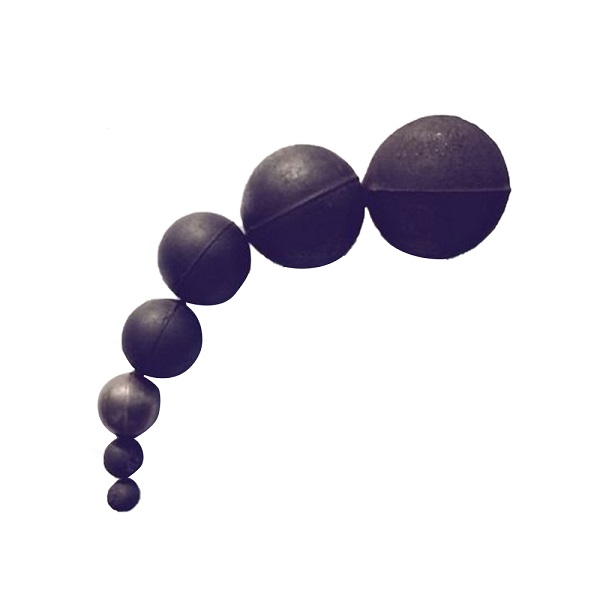

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for High Quality Sag Mill Bolts - Support Roller – H&G , The product will supply to all over the world, such as: New Orleans, Vancouver, United Arab emirates, We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!