Grinding Ball Mill SAG Mill AG Mill and Rod Mill Use High Manganese Ball Mill Liner

Short Description:

Product Description

Manganese Steel Ball Mill Liner in general refers to a kind of casting steel with the Manganese content at 11%~22%, the carbon content at 0.9%~1.5%, mostly higher than 1.0%. Under low impact load, Manganese Steel Ball Mill Liner can achieve HB300~400, Under high impact load, can achieve HB500~800. Different impact load, the Manganese Steel Ball Mill Liner's surface hardening layer depth can be up to 10~20 mm. High hardness of hardening layer can resist the wear of grinding media. Under the condition of strong impact abrasive wear, Manganese Steel Ball Mill Liner has excellent anti-wear performance, so Manganese Steel Ball Mill Liner widely used in mining, aggregates, coal industries as wear-resistant parts.

Note: Depending upon the various application, we propose suitable profile with appropriate alloy ranging from 12 to 25%.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Ni |

P |

S |

|

|

Manganese Steel Ball Mill Liner |

0.9-1.5 |

0.3-1.0 |

11-22 |

0-2.5 |

0-0.5 |

≤0.05 |

≤0.05 |

≤0.05 |

Physical Property & Microstructure

|

Name |

HB |

Ak(J/cm2) |

Microstructure |

|

Manganese Steel Ball Mill Liner |

≤280 |

≥100 |

A+C |

|

A:Austenite C:Carbide |

|||

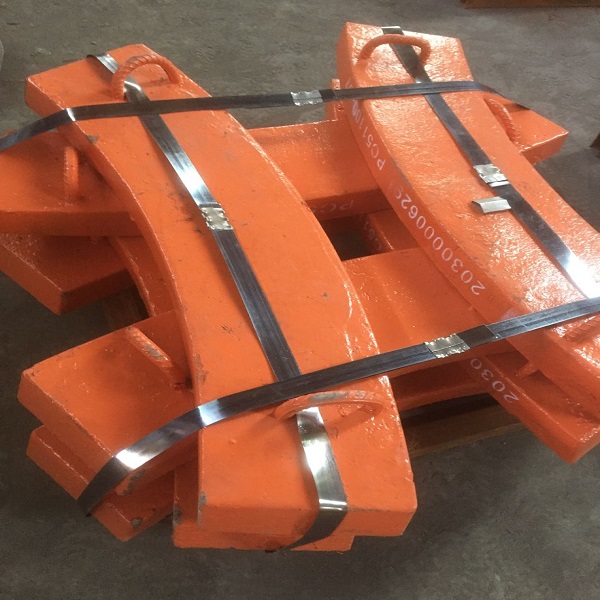

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

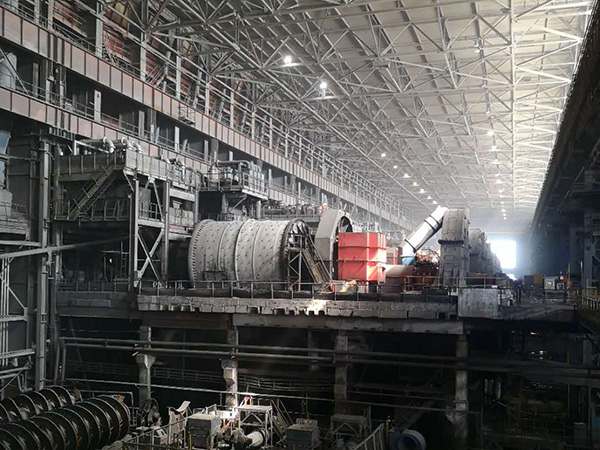

One of the most common types of grinding machines used today in many industries is a ball mill. This device works by using mass media balls made of solid materials, embedded in a compartment or container, in such a way that the material is crushed and powdered at the time of the cavity of the compartment on the material.

To be Today, the use of ball mill is very large because the design and production of ball mill is not very complicated, and it can be easily worked with.

But what matters is the kind of ball mill structure and design, and even the choice of what’s inside the compartment, the type of balls and the conditions in which the mill is supposed to work, and the type of material to be mined, is also very important. There are a lot of empirical and scientific knowledge suggests that ball mills are not organized properly in working conditions.

The main reason is that the increase of the ball mill is not an easy task, and it is always necessary to choose a good ball mill suitable for many working conditions and costs.

The designs and structures of the Ball mill liners are very diverse, and therefore, there are many types of ball mill lines, sizes, designs, and even ball mill liner profiles in many factories and production lines.

The great advantage of using a ball mill is a long life, long durability and maintenance costs that is very low. The chamber or shell in which the balls are fitted are well closed and protected, and along with the ball mill liner components, the ball mill liner is fully charged.

Having a smart design and precision in the design of the ball mill liners are one of the most important factors that contribute to the useful function and long life of the ball mill.

In order to make the ball mill Liners easy to move on the shell plates without any change, the design and construction of lifter bars should be carefully and precisely, and for this purpose it is necessary to easily lifter bars outlast lifter bars by two to one. It should also be designed and constructed lift bar in such way that is compatible with all types of shells and sticky plates, which requires a lot of engineering knowledge and principles.

In fact, a ball mill with lifter bar must be designed and constructed so that it can be easily used for most factories and for specific and general purposes in different situations.

Due to the variety of industries that use ball mills, our experts in the HG Casting have been designing and manufacturing a variety of ball mill liners specially designed and fully functional for different applications tailored to the needs of our customers.

Extremely precise design, high quality materials, custom-made construction, real-world service delivery, and the use of highly skilled and highly skilled technicians have made HG Casting one of the finest manufacturers of ball mill liner.

High-quality HG’s ball mill liner are designed and manufactured to provide customers with confidence that, based on their high performance, they can meet their diverse needs and deliver maximum productivity. These ball mill liners are entirely constructed using rubber sheets and first grade liners and have real warranties.