Fast delivery Mn13cr2 - Carbon alloy steel mill liner – H&G

Short Description:

Fast delivery Mn13cr2 - Carbon alloy steel mill liner – H&G Detail:

Product Description

Carbon Alloy Steel Mill Liner in general refers to a kind of casting steel with the chromium content at 2%~6%, the carbon content at 0.3%~1.2%. Carbon Alloy Steel Mill Liner’s distinctive feature is to adopt multivariate alloy design. Carbon Alloy Steel Mill Liner increases carbide content in the medium carbon alloyed steel, through increasing the Cr & Mo content, the strong carbide forming elements, so as to improve its heat-resisting, wear-resisting performance. As a result, its high strength, strong toughness and good wear resistance properties represent the relatively high level of metal wear resistant materials.

Carbon Alloy Steel Mill Liner is widely used for power coal ball mill, cement mills.

Specification Available

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High C Cr & Mo Liner ZG90Cr5MoRe |

0.6-1.2 |

≤1.0 |

o.4–1.2 |

4-6 |

0.3-1 |

0-0.5 |

≤0.06 |

≤0.06 |

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

Low C Cr & Mo Liner ZG35CrMoRe |

0.3-0.5 |

≤1.0 |

o.6–1.2 |

1.5-2.5 |

0.3-1 |

0-0.5 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

|

Name |

HRC |

Ak(J/cm2) |

Microstructure |

|

High C Cr & Mo Liner ZG90Cr5MoRe |

≥48 |

≥15 |

M+C |

|

Low C Cr & Mo Liner ZG35CrMoRe |

≥42 |

≥50 |

M+C |

|

M-Martensite C- Carbide |

|||

Note: Adjust the chemical content or add other alloying elements of Ball Mill Liner according to customer needs is available.

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

Our White Iron Ball Mill Liner are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

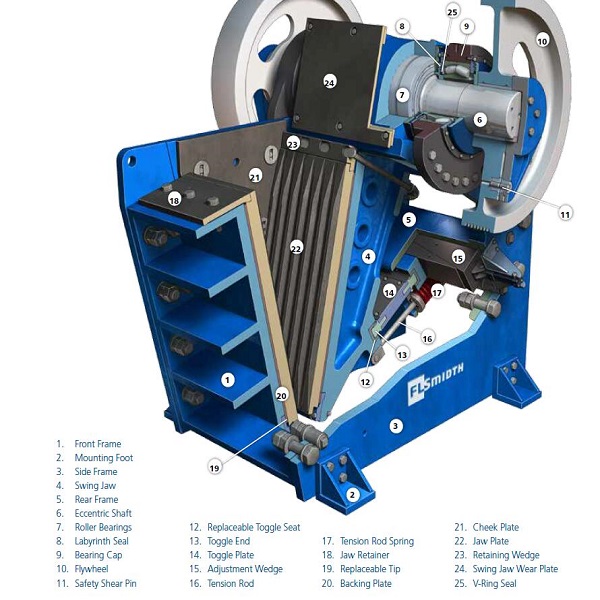

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for Fast delivery Mn13cr2 - Carbon alloy steel mill liner – H&G , The product will supply to all over the world, such as: Finland, Boston, Argentina, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.