Fast delivery Casting Grinding Balls - Cement Grinding Ball – H&G

Short Description:

Fast delivery Casting Grinding Balls - Cement Grinding Ball – H&G Detail:

Product Description

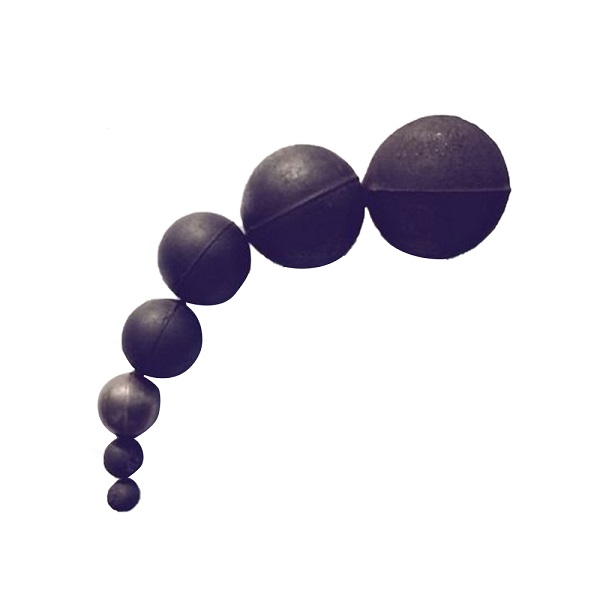

Grinding Ball size range from 12-125 mm, 45-65 HRC, 1-23 % Cr. content.

Grinding Cylpeb of required sizes 45-65 HRC, 1-23 % Cr. content.

The Grinding Media is produced by full-Auto casting lines, certified under international quality standards.

We guarantee our Grinding Ball has low breakage rate, lower wear of consumption, and fast delivery terms.

Specification Available

|

Name |

Chemical Element(%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

2.0-3.3 |

≤1.0 |

0.3-1.5 |

10-23 |

0-3.0 |

0-1.2 |

≤0.06 |

≤0.06 |

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

1.8-3.6 |

≤1.5 |

0.3-1.5 |

1-6 |

0-1.0 |

0-0.8 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

| Name |

Hardness (HRC) |

Impact Ak(J/cm2) |

Microstructure |

Times of Falling Balls |

||

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥60 |

≥4.0 |

M+C+A |

≤Φ80 |

≥15000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥45 |

≥2.5 |

P+C |

≤Φ80 |

≥12000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

M-Martensite C-Carbide A-Austenite P-Pearlite |

||||||

Grinding Ball Specification

|

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

|

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

|

Φ17 |

0.027 |

37037 |

Φ70 |

1.37 |

729 |

|

|

Φ20 |

0.032 |

31250 |

Φ80 |

2.05 |

487 |

|

|

Φ30 |

0.11 |

9091 |

Φ90 |

2.90 |

345 |

|

|

Φ40 |

0.25 |

3891 |

Φ100 |

4.00 |

250 |

|

|

Φ50 |

0.50 |

2000 |

Φ110 |

5.30 |

188 |

|

|

Φ60 |

0.86 |

1153 |

Φ120 |

6.80 |

147 |

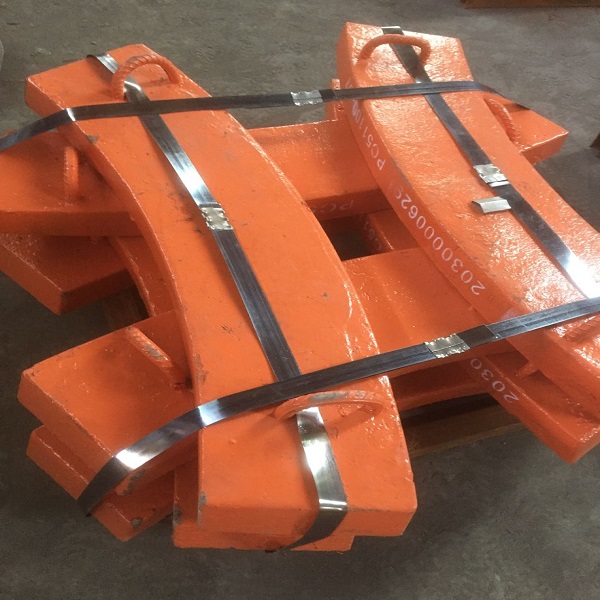

Product Package

● Nylon Ton Bag: Net Weight: 1000 kgs; Gross Weight: 1002kgs

● Steel Drum: Net Weight: 850 – 900 kgs; Gross Weight: 865 – 915 kgs

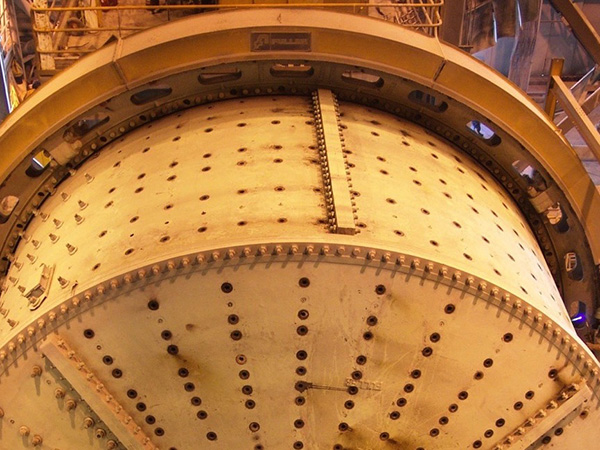

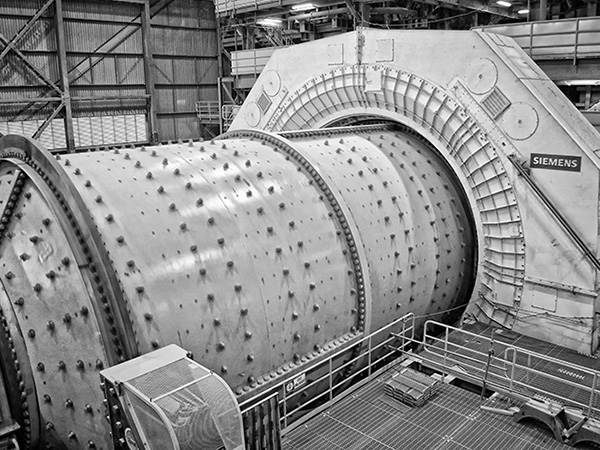

Application

Grinding balls are used to grind or blend materials. A grinding ball works on the principle of impact and attrition. Earlier balls were made from steel, ceramic or rubber. These days they are much more scientific and Magotteaux manufactures them in alloys which are especially suited to the tasks they have to perform creating less wear and far greater efficiency in production. We will give you advice on which balls are best for your specific needs.

The choice of grinding media will always depend on the material to be ground. You need to assess its granulometry and the grinding process. You also need to look at the relative importance of the wear mechanisms in the process.

High-Chrome grinding media combines martensitic structure with hard chrome carbides, This provides the best wear resistance against corrosion and abrasion of all kinds. HG´s expertise enables them to select the alloy which fits your application perfectly and minimizes the costs. High-Chrome media has a superior performance and creates steady milling conditions due to its low wear rate. For each specific alloy there is a constant hardness of all grinding media. This creates a positive influence in the down-stream process. high-Chrome media is suitable for both wet and dry ore applications in ball mills and tower mills.

Product detail pictures:

Related Product Guide:

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for Fast delivery Casting Grinding Balls - Cement Grinding Ball – H&G , The product will supply to all over the world, such as: Cairo, Croatia, Swansea, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!