Factory directly Mill Liner Plates – Mining Wear Parts Metso Mining Equipments Chute and Hopper Liner – H&G

Short Description:

Factory directly Mill Liner Plates – Mining Wear Parts Metso Mining Equipments Chute and Hopper Liner – H&G Detail:

Product Description

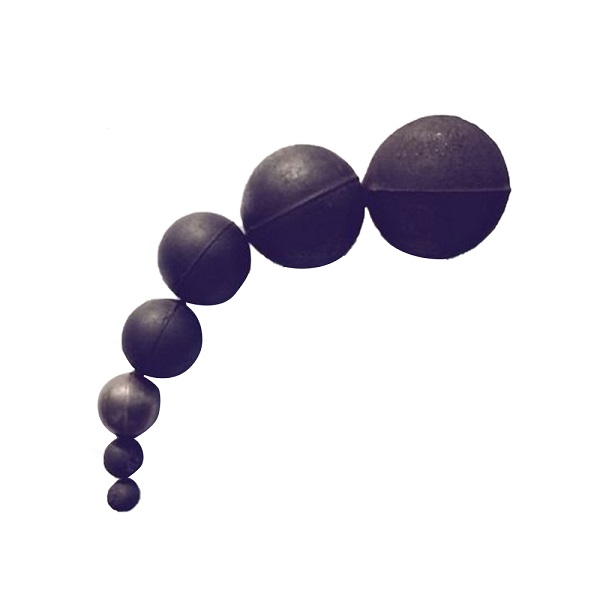

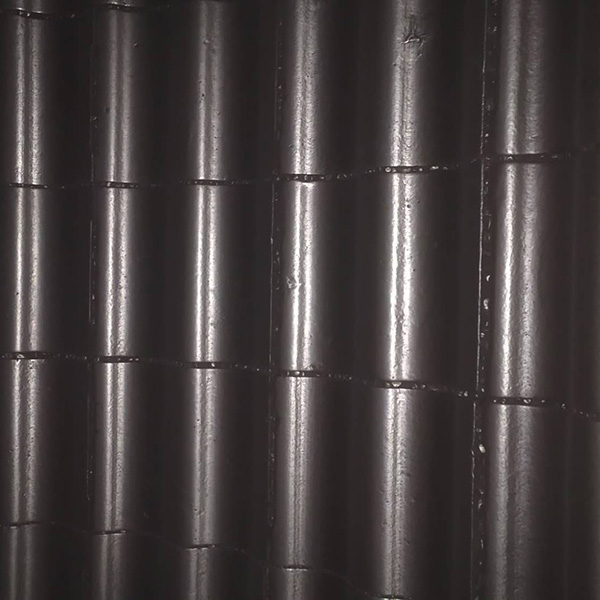

White Iron Ball Mill Liner in general refers to the alloy white iron with the chromium content at 12%~26%, the carbon content at 2.0%~3.6%. White Iron Ball Mill Liner distinctive features is that the M7C3 type eutectic carbide micro hardness is HV1300~1800. White Iron Ball Mill Liner’s eutectic carbide is distributed on the base, martensite(the most hard metal matrix organization), in discontinuous network and isolation, which reduces the fragmentation of the matrix effect. As a result, the high chromium Ball Mill Liner has high strength, strong toughness and good wear resistance features , which is widely used at Mining ,Cement and power industry.

White Iron Ball Mill Liner is recommended to be using at low impact working condition such as:

1. Belt conveyor liner for Mining industry.

2. Cement plant Ball Mill.

3. Chemical industry Ball Mill.

Chemical Elements

|

Name |

Chemical Elements (%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High Cr Ball Mill Liner Cr26 |

2.5-3.3 |

0-0.8 |

≤2.0 |

23–28 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

|

High Cr Ball Mill Liner Cr15 |

2.3-3.3 |

0-0.8 |

≤2.0 |

14–18 |

≤3.0 |

≤1.2 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

|

Name |

HRC |

Ak(J/cm2) |

Microstructure |

|

High Cr Ball Mill Liner Cr26 |

≥58 |

≥3.5 |

M+C+A |

|

High Ball Mill Liner Cr15 |

≥52 |

≥4.5 |

M+C+A |

|

M-Martensite C- Carbide A-Austenite |

|||

Note: Adjust the chemical content or add other alloying elements of Ball Mill Liner according to customer needs is available.

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Application

Our White Iron Ball Mill Liner are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

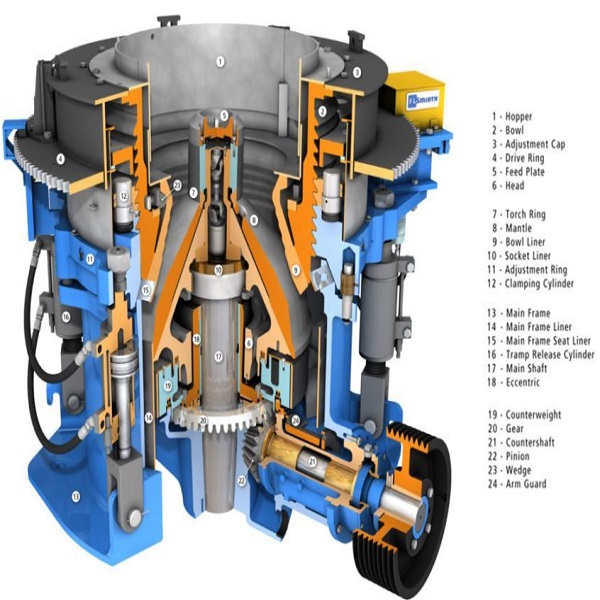

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

When it comes to chrome moly white iron mill liners, H&G Mill Liners had focused this material for long time. Our chrome moly white iron mill liners span life more than other foundries mill liners.

This cast material is considered to be the ultimate developed and used to date for abrasion resistance in Milling. It is commonly used in cement mills and some of the largest Ball Mills in the world and where performance has not been bettered to date.

The Features

- 600 to 700 BHN white iron

- Large ball mills

- Malleable Iron: cast as white iron,then malleabilised, or heat treated, to impart ductility. Consists of tempered graphite in an a-ferrite or pearlite

matrix - Common in cement mills

- Used for abrasion resistance

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Factory directly Mill Liner Plates – Mining Wear Parts Metso Mining Equipments Chute and Hopper Liner – H&G , The product will supply to all over the world, such as: Mexico, India, Czech republic, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!