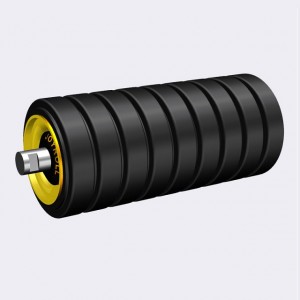

Conveyor Roller

Short Description:

SPECIFICATION

Roller Diameter: 89, 102, 108, 114, 127, 133, 140, 152, 159, 165, 178, 194, 219mm

Roller Length: 100-2400mm.

Shaft Diameter: 20, 25, 30, 35, 40, 45, 50mm

Bearing type: 6204, 6205, 6305, 6206, 6306, 6307, 6308, 6309, 6310

Standard: DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

CONVEYOR ROLLER

Rollers are an important part of the entire conveyor belt system. A high quality roller will increase the life of the entire system. H&G rollers are characterized by a low rolling resistance, a very small quantity of radial vibration as well as an excellent performance of balance. These features lead to energy saving, a very low noise even at high speed, and therefore to economic and environment-friendly conveying operations.

H&G rollers can be fabricated according to DIN, AFNOR, CEMA, BS, FEM, JIS and many other international standards with different type of shaft end.

Usually working as roller sets in different angle, the rollers help to balance the belt and ensure the troughing. The carrying rollers are the most common roller type in a belt conveyor system.

Guarantees the stability of a belt in the lower run of the conveyor belt.

Guide rollers – also called side rollers – protect the belt from deviation, usually designed with only one side spindle fixed to the frame.

A special type of return roller also called clean roller, covered with sharp edge rubber discs, spaced in the middle area of the roller to clean the sticky material on the belt cover, and flat rubber discs at both ends of the roller, which protects the belt edge from damage.

A special type of carrying roller fully covered with flat rubber discs that absorbs impact energy at the loading point when bulk material is dropping.