Chinese Professional Cement Ball - Grinding ball and grinding cylpebs – H&G

Short Description:

Chinese Professional Cement Ball - Grinding ball and grinding cylpebs – H&G Detail:

Product Description

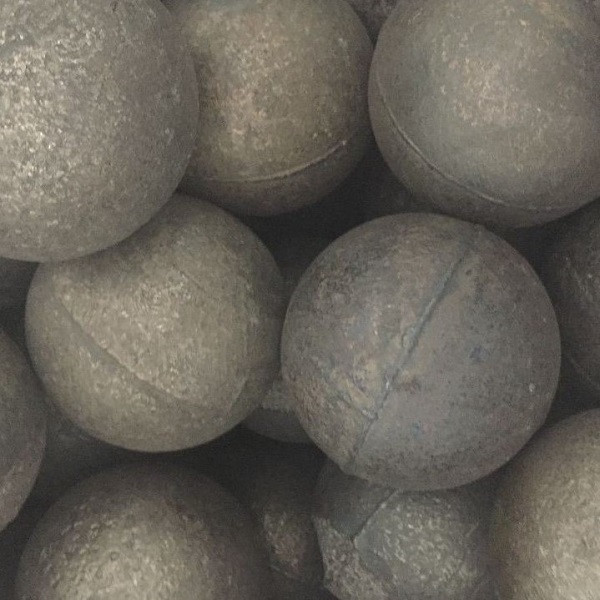

Grinding Ball size range from 12-125 mm, 45-65 HRC, 1-23 % Cr. content.

Grinding Cylpeb of required sizes 45-65 HRC, 1-23 % Cr. content.

The Grinding Media is produced by full-Auto casting lines, certified under international quality standards.

We guarantee our Grinding Ball has low breakage rate, lower wear of consumption, and fast delivery terms.

Specification Available

|

Name |

Chemical Element(%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

2.0-3.3 |

≤1.0 |

0.3-1.5 |

10-23 |

0-3.0 |

0-1.2 |

≤0.06 |

≤0.06 |

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

1.8-3.6 |

≤1.5 |

0.3-1.5 |

1-6 |

0-1.0 |

0-0.8 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

| Name |

Hardness (HRC) |

Impact Ak(J/cm2) |

Microstructure |

Times of Falling Balls |

||

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥60 |

≥4.0 |

M+C+A |

≤Φ80 |

≥15000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥45 |

≥2.5 |

P+C |

≤Φ80 |

≥12000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

M-Martensite C-Carbide A-Austenite P-Pearlite |

||||||

Grinding Ball Specification

|

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

|

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

|

Φ17 |

0.027 |

37037 |

Φ70 |

1.37 |

729 |

|

|

Φ20 |

0.032 |

31250 |

Φ80 |

2.05 |

487 |

|

|

Φ30 |

0.11 |

9091 |

Φ90 |

2.90 |

345 |

|

|

Φ40 |

0.25 |

3891 |

Φ100 |

4.00 |

250 |

|

|

Φ50 |

0.50 |

2000 |

Φ110 |

5.30 |

188 |

|

|

Φ60 |

0.86 |

1153 |

Φ120 |

6.80 |

147 |

Grinding Cylpeb Specification

|

Size(mm) |

Ф10series |

Ф12series |

Ф14series |

Ф16series |

Ф18series |

Ф20series |

|

Ф25series |

Ф30series |

Ф35series |

Ф40series |

Ф45series |

Ф50series |

Note: Adjust the chemical content or add other alloying elements of Grinding Ball and Grinding Cylpeb according to customer needs is available.

Product Package

● Nylon Ton Bag: Net Weight: 1000 kgs; Gross Weight: 1002kgs

● Steel Drum: Net Weight: 850 – 900 kgs; Gross Weight: 865 – 915 kgs

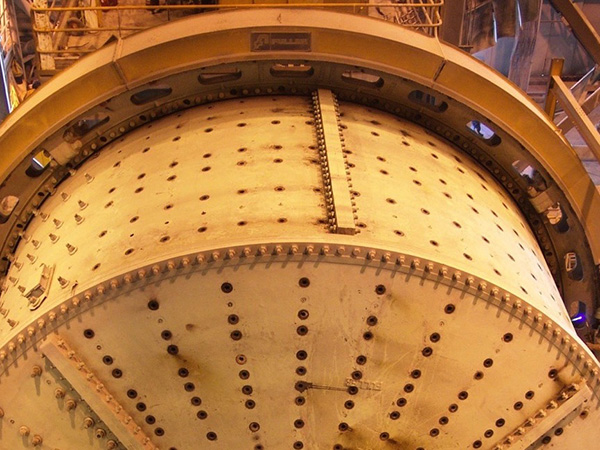

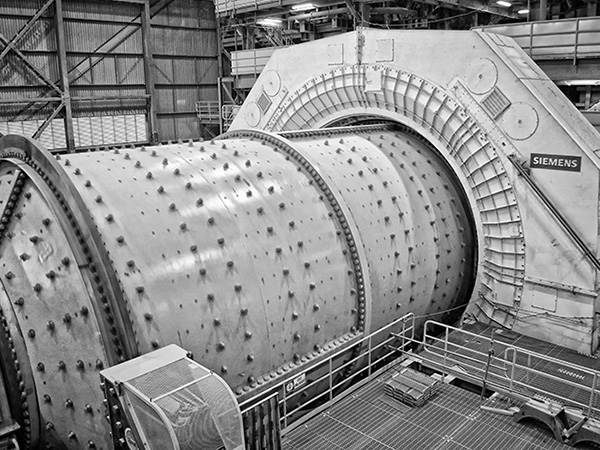

Application

Our Grinding Ball and Grinding Cylpeb are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for Chinese Professional Cement Ball - Grinding ball and grinding cylpebs – H&G , The product will supply to all over the world, such as: Chile, Jamaica, Jordan, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.