China Wholesale Mobile Ball Mill Manufacturers - Metso SAG Mill Shell Liner and Feeding Discharge Innner and Outer Mill Liner – H&G

Short Description:

China Wholesale Mobile Ball Mill Manufacturers - Metso SAG Mill Shell Liner and Feeding Discharge Innner and Outer Mill Liner – H&G Detail:

Product Description

SAG Mill Liner from H&G use Cr-Mo materials (AS2074 Standard), SAG Mill Liner provides superior impact and wear resistance in all semi-autogenous milling applications.

To choose the right material for the right application is our mission , we are always working together with our customer to achieve this .The right material is upon to:

1. The mineral ground

2. Milling data information

3. Maximum grinding media diameter (mm)

4. Grinding media filling degree (%)

In general, Item M1 used for high impact condition ,P1 used for low impact condition. It shall change according to your mineral processing.

Specification Available

|

Code |

Chemical Elements(%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

P1 |

0.6-0.9 |

0.4-0.7 |

0.6-1.0 |

1.8-2.5 |

0.25-0.5 |

0-0.5 |

≤0.04 |

≤0.06 |

|

M1 |

0.3-0.45 |

0.4-0.7 |

1.3-1.6 |

2.5-3.5 |

0.6-0.8 |

0-0.5 |

≤0.04 |

≤0.06 |

Physical Property & Microstructure

|

Code |

Hardness(HB) |

Ak(J/cm2) |

Microstructure |

|

P1 |

325-375 |

≥50 |

P |

|

M1 |

350-400 |

≥75 |

M |

|

M-Martensite, C-Carbide, A-Austenite, P-Pearlite |

|||

Note: Adjust the chemical content or add other alloying elements of SAG Mill Liner according to customer needs is available.

Product Package

● Steel Pallet, Wooden Pallet and Wooden Box

● Customized according to special packing requirement.

Our Advantage

At HG Casting, we engineer innovative designs, tailored especially for every customer. Our AG/SAG mill liners are manufactured to the highest industry standard for Autogenous Grinding(AG), Semi-Autogenous Grinding(SAG), Primary / Secondary and re-grind rod or ball mills. MGS Casting mill lining system designed by our highly trained, and dedicated team throughout the world has taken your entire comminution circuit into consideration. Supporting our front line Mill Engineers is a large team of extremely specialized design engineers, material chemists, manufacturing and logistics experts responsible for delivering exceptional service.

Optimal mill designs engineered by our team take into consideration service life; grind & power efficiency and ore characteristics, along with costumer circuit constraints both up and downstream of the mill lining.

HG Casting had success to use ASTM 2074/L2B alloy steel to manufacture AG/SAG mill liners. Under this material, our mill liners span life can be obviously improved. Our Australia customers had ordered more than 10,000 tons per year of this material mill liners.

As a casting foundry, HG Casting also has own SAG mill liner design. In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be considered. Each of these topics has had a considerable amount of research, and numerous case studies of evolutionary liner design have been published. Based on experience, mill liner designs have moved toward more open shell lifter volumetric capacity and a grate design to facilitate maximizing both pebble-crushing circuit utilization and SAG mill capacity. Mill throughput is maximized with shell lifters between ratios of 2.5:1 and 5.0:1. This ratio range is stated without reference to face angle; At equivalent spacing-to-height ratios, lifters with greater face angle relief will have less packing problems when new but experience higher wear rates than those with a steeper face angle. Pulp lifter design can be a significant consideration for SAG mills, particularly for large mill. All mill sizes increases, the required volumetric capacity of the pulp lifters grows proportionally to mill volume.

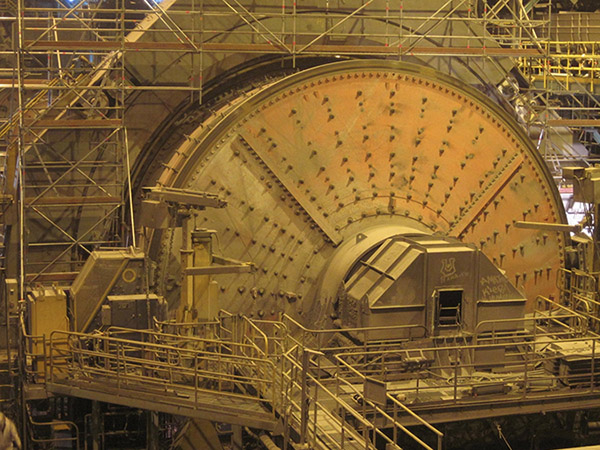

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for China Wholesale Mobile Ball Mill Manufacturers - Metso SAG Mill Shell Liner and Feeding Discharge Innner and Outer Mill Liner – H&G , The product will supply to all over the world, such as: Kyrgyzstan, Wellington, Cairo, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.