China Wholesale Iron mining Factory - Ball Mill Grinding Ball – H&G

Short Description:

China Wholesale Iron mining Factory - Ball Mill Grinding Ball – H&G Detail:

Product Description

HG supply grinding balls for the mining, cement, steel plant, power plant, aggregates etc industries. According to the working conditions, we could supply casting, forged, high Cr, low Cr, high C, low C grinding balls.

For the casting balls, we are using our unique metallic molding casting process, which will have higher microstructure density comparing to normal sand molding line. Adding unique heat treatment technology, our balls will offer lower wear rate.

Specification Available

|

Name |

Chemical Element(%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

2.0-3.3 |

≤1.0 |

0.3-1.5 |

10-23 |

0-3.0 |

0-1.2 |

≤0.06 |

≤0.06 |

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

1.8-3.6 |

≤1.5 |

0.3-1.5 |

1-6 |

0-1.0 |

0-0.8 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

| Name |

Hardness (HRC) |

Impact Ak(J/cm2) |

Microstructure |

Times of Falling Balls |

||

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥60 |

≥4.0 |

M+C+A |

≤Φ80 |

≥15000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥45 |

≥2.5 |

P+C |

≤Φ80 |

≥12000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

M-Martensite C-Carbide A-Austenite P-Pearlite |

||||||

Grinding Ball Specification

|

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

|

|

Φ17 |

0.027 |

37037 |

Φ70 |

1.37 |

729 |

|

|

Φ20 |

0.032 |

31250 |

Φ80 |

2.05 |

487 |

|

|

Φ30 |

0.11 |

9091 |

Φ90 |

2.90 |

345 |

|

|

Φ40 |

0.25 |

3891 |

Φ100 |

4.00 |

250 |

|

|

Φ50 |

0.50 |

2000 |

Φ110 |

5.30 |

188 |

|

|

Φ60 |

0.86 |

1153 |

Φ120 |

6.80 |

147 |

Product Package

● Nylon Ton Bag: Net Weight: 1000 kgs; Gross Weight: 1002kgs

● Steel Drum: Net Weight: 850 – 900 kgs; Gross Weight: 865 – 915 kgs

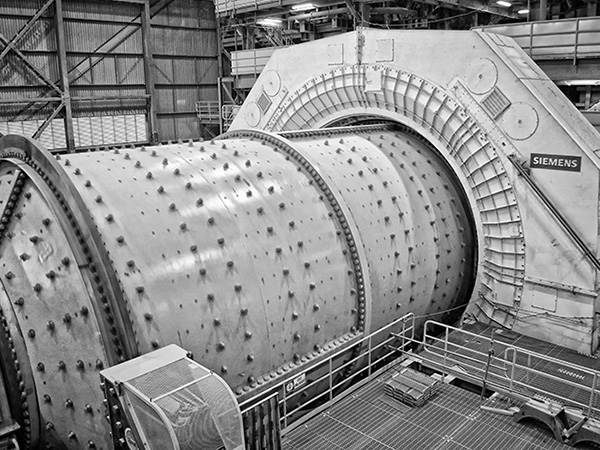

Application

As in general grinding ball manufactured from steel and cast iron. It has various applications in that grinding purpose is what stands at first. Be the miling particles are moisture or dry it will grind. Mostly these balls are used in the manufacturing process. There are various types of balls. Each of the balls has specific features it means a lot for the special production process.

When comes to milling and dispersion process there are more chances for material damage and then splits. In order to avoid such thing grinding balls are used. The balls are made of heavy metal and other material thus undoubtedly there the pressure will be high. If the pressure gets impacted on the material then it will offer pressure to the particles. It will completely reduce the size of the particle at the same time you will have resulted with finite particles. In short, contamination is the actual reason to use grinding balls. It will make the particles to decrease in size.

When you choose grinding ball then you will certainly gain the following benefits. Here comes,

· Be it wet or dry you will get the faster and efficient grinding process

· It will bear high heat as well as chemical resistance

· You can reduce the heat production in the process of grinding

· Regardless of the particle size at the beginning, it will completely reduce and then offer a finite-sized particles

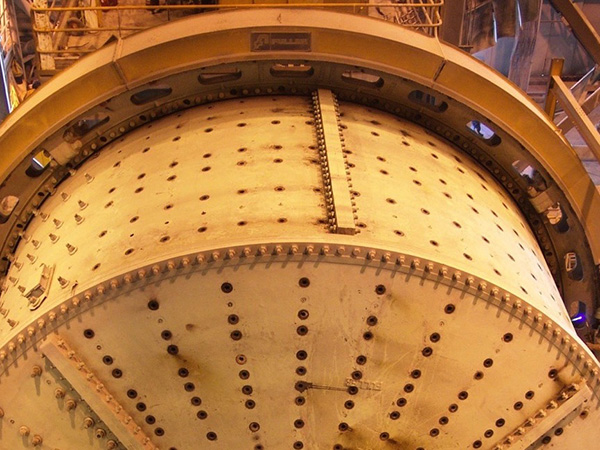

Product detail pictures:

Related Product Guide:

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for China Wholesale Iron mining Factory - Ball Mill Grinding Ball – H&G , The product will supply to all over the world, such as: Paraguay, Rotterdam, Spain, Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.