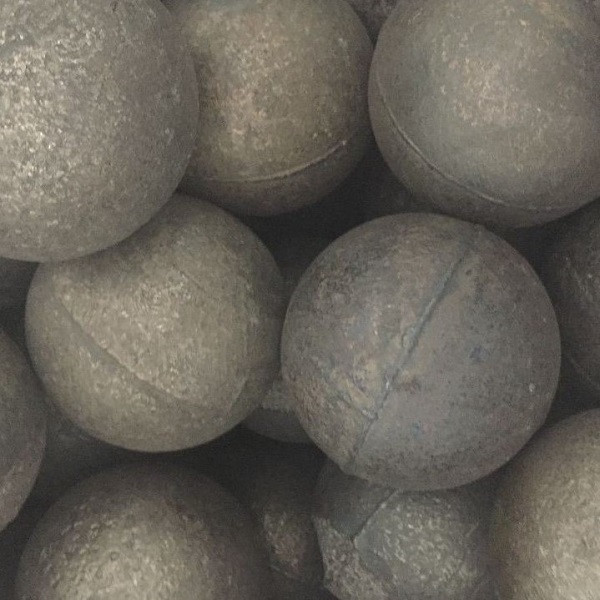

100% Original Casting Grinding Cylpebs - Grinding ball and grinding cylpebs – H&G

Short Description:

100% Original Casting Grinding Cylpebs - Grinding ball and grinding cylpebs – H&G Detail:

Product Description

Grinding Ball size range from 12-125 mm, 45-65 HRC, 1-23 % Cr. content.

Grinding Cylpeb of required sizes 45-65 HRC, 1-23 % Cr. content.

The Grinding Media is produced by full-Auto casting lines, certified under international quality standards.

We guarantee our Grinding Ball has low breakage rate, lower wear of consumption, and fast delivery terms.

Specification Available

|

Name |

Chemical Element(%) |

|||||||

|

C |

Si |

Mn |

Cr |

Mo |

Cu |

P |

S |

|

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

2.0-3.3 |

≤1.0 |

0.3-1.5 |

10-23 |

0-3.0 |

0-1.2 |

≤0.06 |

≤0.06 |

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

1.8-3.6 |

≤1.5 |

0.3-1.5 |

1-6 |

0-1.0 |

0-0.8 |

≤0.06 |

≤0.06 |

Physical Property & Microstructure

| Name |

Hardness (HRC) |

Impact Ak(J/cm2) |

Microstructure |

Times of Falling Balls |

||

|

High-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥60 |

≥4.0 |

M+C+A |

≤Φ80 |

≥15000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

Low-Cr Alloyed Grinding Ball and Grinding Cylpeb |

≥45 |

≥2.5 |

P+C |

≤Φ80 |

≥12000 |

|

|

≥Φ80 |

≥10000 |

|||||

|

M-Martensite C-Carbide A-Austenite P-Pearlite |

||||||

Grinding Ball Specification

|

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

|

Size(mm) |

Weight(kg) |

Quantity(pc/t) |

|

Φ17 |

0.027 |

37037 |

Φ70 |

1.37 |

729 |

|

|

Φ20 |

0.032 |

31250 |

Φ80 |

2.05 |

487 |

|

|

Φ30 |

0.11 |

9091 |

Φ90 |

2.90 |

345 |

|

|

Φ40 |

0.25 |

3891 |

Φ100 |

4.00 |

250 |

|

|

Φ50 |

0.50 |

2000 |

Φ110 |

5.30 |

188 |

|

|

Φ60 |

0.86 |

1153 |

Φ120 |

6.80 |

147 |

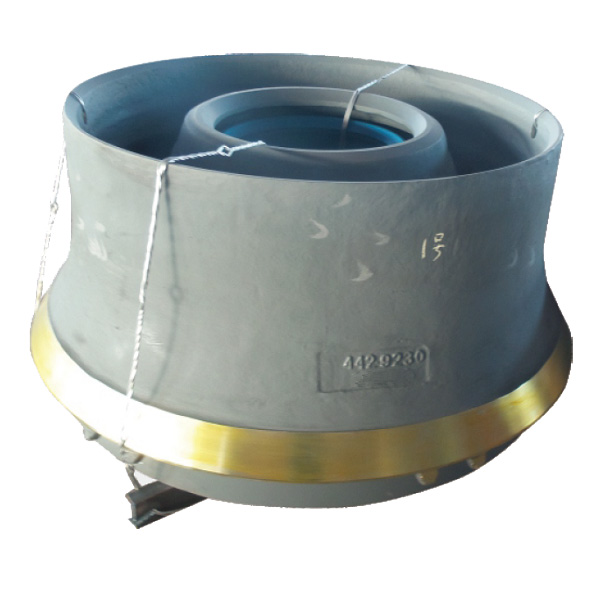

Grinding Cylpeb Specification

|

Size(mm) |

Ф10series |

Ф12series |

Ф14series |

Ф16series |

Ф18series |

Ф20series |

|

Ф25series |

Ф30series |

Ф35series |

Ф40series |

Ф45series |

Ф50series |

Note: Adjust the chemical content or add other alloying elements of Grinding Ball and Grinding Cylpeb according to customer needs is available.

Product Package

● Nylon Ton Bag: Net Weight: 1000 kgs; Gross Weight: 1002kgs

● Steel Drum: Net Weight: 850 – 900 kgs; Gross Weight: 865 – 915 kgs

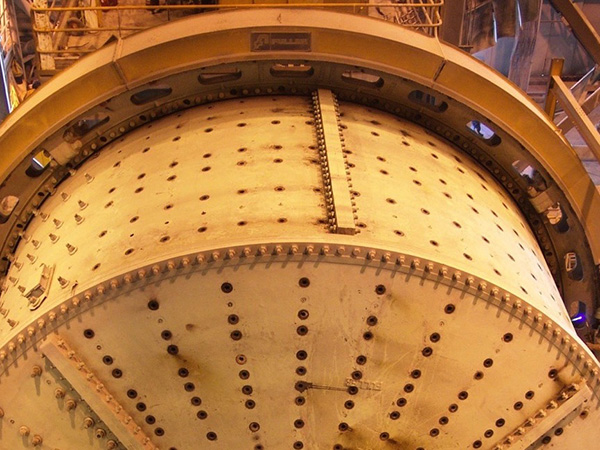

Application

Our Grinding Ball and Grinding Cylpeb are widely used in the grinding stage for mining industry, cement industry, thermal power plant, paper-making and chemical industry etc.

Product detail pictures:

Related Product Guide:

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for 100% Original Casting Grinding Cylpebs - Grinding ball and grinding cylpebs – H&G , The product will supply to all over the world, such as: Malta, Tajikistan, Gabon, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to provide professional, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We will serve you with all sincerity!

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.